Everyone's a winner!

Our consulting services for optimising manufacturing costs guarantees successMany metal processing companies are aware of the situation: Intensifying competitive conditions mean increased pressure to reduce costs and improve the efficiency of all processes. Our consulting service for optimising manufacturing processes helps you keep costs under control and improve your long-term competitiveness on the market. The service can also help you consolidate existing business relationships and build new ones. So the bottom line is: everyone's a winner!

Your benefits at a glance:

- Use our expertise to optimise your production planning

- Reduce the total cost of ownership using optimised manufacturing strategies

- Reduce your workpiece costs sustainably and with success guaranteed

We take on your problem so we can solve it together

Over the past few years, we have helped numerous customers to solve issues relating to planning manufacturing processes in the metal processing industry. We have an in-depth understanding of the challenges faced by production planners in small- and medium-sized companies. We use our accumulated expertise to provide efficient production planning solutions.

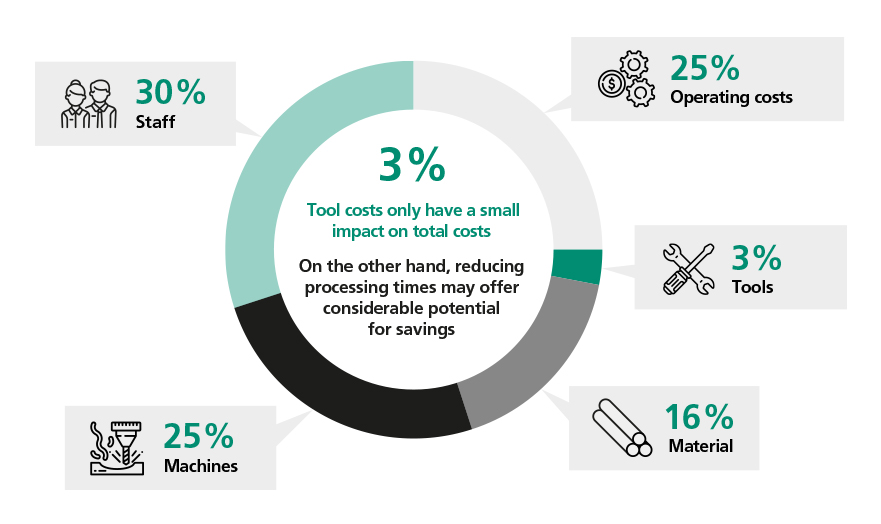

Purchasing and production departments often have different ideas about which tools and consumables to choose, as often the easiest place to make initial savings is the tools. Procurement costs are usually transparent, so they are usually subject to a high level of pressure in terms of pricing and discounts. But is this the wrong place to make savings? Our analyses show that the cost of tools only accounts for around three percent of the total cost of a workpiece — so even big savings on tools bear little effect on the unit cost of the workpiece. Costs during production cannot be reduced in the same way:

Our service: Optimised production process planning

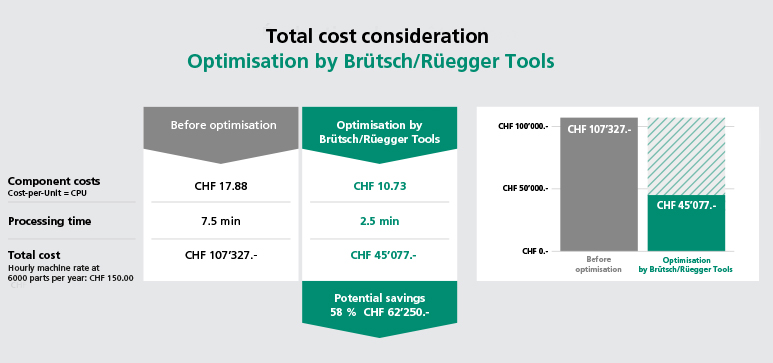

In spite of this, we understand that carefully selecting machine tools and optimising the planning process for workpiece processing have a direct impact on the production process and therefore on the reduction of cost per unit (CPU). Less time is required, there is less wear and the required precision can be maintained — ticking the boxes for company objectives. We can demonstrate that accelerating machining processes and reducing error rates are very effective ways to significantly reduce total costs. We can also prove that total costs can be significantly reduced even when using high-quality tools at a higher purchase price.

Our advice is always based on detailed analysis of the actual situation. The selected materials, component geometry and machining process are all closely examined: Which tools are used? How are the individual processing steps planned? Small details often hide enormous potential for savings. Our application specialists use this analysis to develop an optimised production concept that is tailored specifically to your requirements. Our work always results in a cost reduction — success is guaranteed!

Planning and implementation from a single source

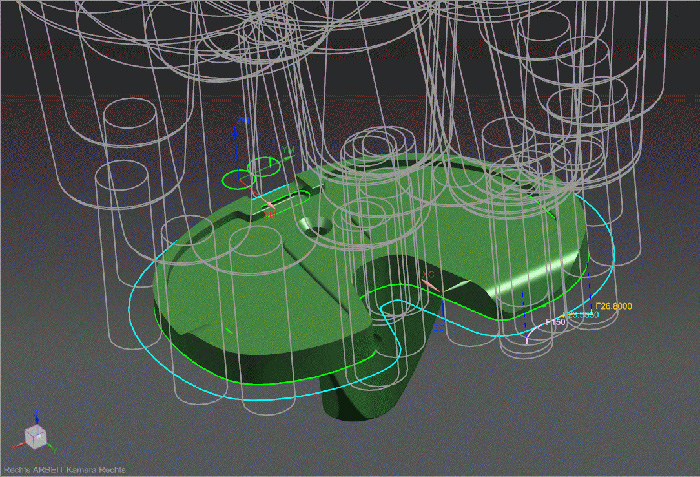

We use hyperMILL modular CAM software to plan and optimise production processes. This software can be used to program 2.5D, 3D and 5-axis milling as well as mill turning and machining operations such as high-speed cutting (HSC) and high-performance cutting (HPC) on a single platform. A CNC universal milling machine in our SmartFactory is used as a practical tool to develop an optimal planning process. Our application specialists use a wide range of approaches, including changing the machining sequence, shortening path lengths, reducing tool changes or adapting tool paths.

Using a simulation as a feasibility study, we prove the load-bearing capacity and practical suitability of the new solution. If the new process is approved, we provide on-site support as your convert your processing machines. The new machining processes are tailored to their specific requirements. You can continue to use the tools that you are familiar with or use new tools to realise your full cost-cutting potential.

A CNC universal milling machine in our own SmartFactory is used to practically develop optimised planning processes.

Minimal customer effort

Companies that use our consulting service benefit from reliable manufacturing processes and an increased profit margin per workpiece. We coordinate and implement the project, so there's very little effort required on your part. We also create a manageable time frame: The entire process takes barely a month from initial analysis to programming the new machine, in contrast to other common lengthy and expensive consulting projects.