Digital quality control at every level

Digital data plays a crucial role in optimising processes. However, it is still all too rarely accessed, analysed and transformed into usable information.

If you want to improve, it is vital to measure your progress and manage your measuring equipment properly at all times. But which measuring devices are compatible with which software tools? Which connections do you need for which measuring tasks? When networking measuring equipment, even tech-savvy users can lose sight of all the various interfaces, connections and other devices.

To save time and avoid any unpleasant surprises, manufacturing companies in this area should seek external assistance as creating a holistic framework for all quality control processes requires in-depth expertise and practical experience.

Expertise in both measuring devices and process digitisation allows Brütsch/Rüegger Tools to support manufacturing companiesin managing measurement processes, measurement methods and measurement data. From setting up measuring stations and connecting measuring equipment to PCs all the way through to analysing measurement data, we advise on and implement professional customer-specific solutions.

New: Hive Digital Suite

Whether it's CNC machines, measuring devices, torque screwdrivers or intralogistics, each step of the process chain generates raw data. In order to structure and transform this data into value-generating information, a holistic platform is required that can manage all the data uniformly and independently of manufacturers. With the brand new Hive Digital Suite , Brütsch/Rüegger Tools has created a long-awaited solution for the MEM industry that is open and can be adapted to suit the user's individual needs. Raphaël Müller, Head of Industrial Solutions at Brütsch/Rüegger Tools, explains: "The new software suite opens up a wide range of unprecedented opportunities, especially in the computer-aid quality assurance—or CAQ—sector."

The Hive Digital Suite runs on Jellix, the open IoT platform co-developed by Brütsch/Rüegger Tools, and includes the following modules: Shop Floor for collecting and evaluating production data, Inventory for material management and Worker Instruction for assembly. Quality Control, the fourth module, simplifies comprehensive quality management processes and finally closes the gap between production and final checks.

Industrial Solutions

Using expertise to take things to the next level

Our Industrial Solutions team has ten years of experience that can help to get a wide variety of projects off the ground. In those ten years, the team has grown to include several experts and now plans, supports and implements custom industrial digitalisation projects.

The services that Brütsch/Rüegger Tools offers are tailored precisely to the MEM industry and are based on our own technological innovation: Our Jellix and Hive Digital Suite digitalisation solutions have been developed using the best IIoT technologies and are constantly being updated and improved. To be able to provide manufacturing companies with holistic support, we also have a wide range of third-party systems. The openness of the systems is at the heart of our philosophy and therefore guarantees long-term and unrestricted operation.

To find out more with no obligation, please contact us on +41 44 736 63 63 or info@brw.ch. Our specialists will be happy to help you with all your questions! You can also visit our SmartFactory in Urdorf and immerse yourself in the fascinating world of industry 4.0.

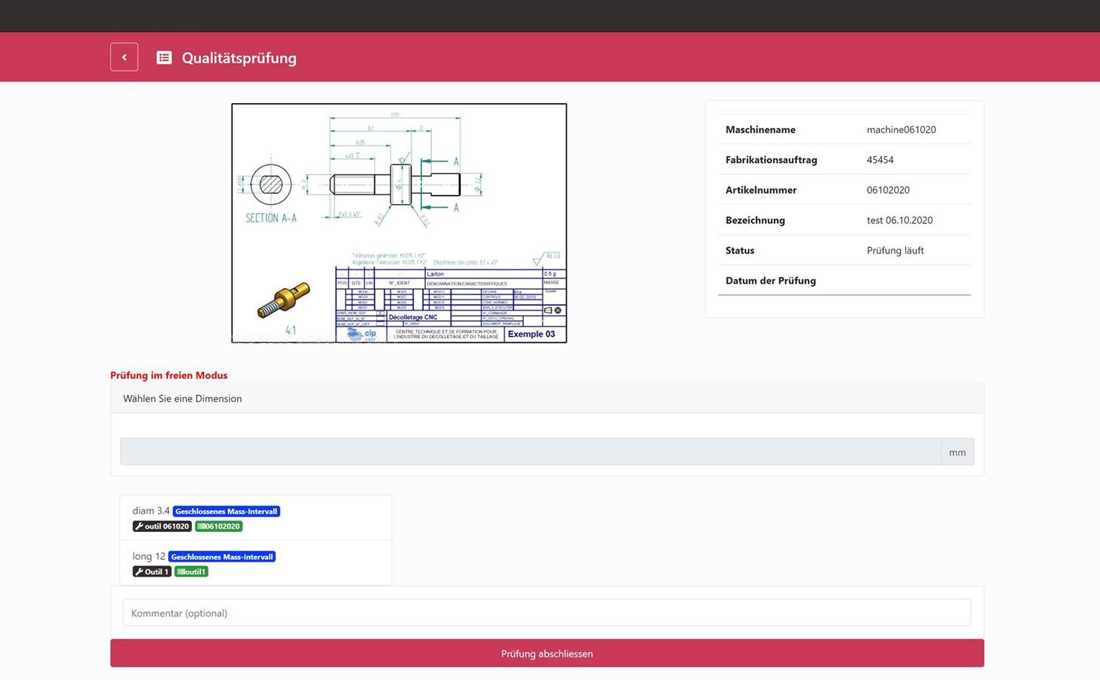

Integrated CAQ solution: quality control

Quality Control is a real all-rounder: The module can be connected to measuring stations and quality control (both in production and final testing) and can be synchronised with third-party ERP, MES or PLM systems. The intelligent CAQ solution visualises measurement data, KPIs and reports on dashboards, provides graphical representations of measurement analyses, detects trends and summarises testing processes. The status of measuring stations and orders, the capacities of machines and personnel as well as reports and messages can be viewed on the PC or any end device — and it can all be adapted to suit the user's needs and criteria. Managing processes, inspection and testing plans as well as control cards is child's play with Quality Control. The module creates transparency about all quality processes in a manufacturing company and provides a solid foundation for increased productivity.

We will accompany you every step of the way in your digital transformation

As an experienced partner for digitalisation, Brütsch/Rüegger Tools not only creates progress analyses, sets goals and designs concepts for its customers, it also actively supports them in the installation of a long-term solution for networked quality control, including follow-up support. For example, during the analysis of measurement data, special attention can also be given to anticipating error detection. Raphaël Müller continues: "In this instance, we proceed systematically by building a flexible and sustainable CAQ architecture."

No matter how complex the matter is, with the help of the easy-to-use Hive Digital Suite, users are always able to keep track of the performance of all quality assurance processes. Our diverse expertise is based on internal innovation projects and a decade of experience, which we pass on to customers in our workshops and training courses.