A look behind the scenes: Brütsch/Rüegger Tools at INNOTEQ 2025

Preparations are in full swing for the INNOTEQ trade fair, which will take place again in Bern from 11 to 14 March. As a leading Swiss tool partner, Brütsch/Rüegger Tools will naturally be there. But simply "being there" is not enough: "When putting together the topics and exhibitions to be presented, our focus was on solutions and products that will help our customers become more efficient, faster and better, while also saving costs and time", explains Olaf Sprich. What is the Head of Sales at Brütsch/Rüegger Tools referring to specifically? "Under the slogan 'Tools. Next Level', we will provide visitors with exclusive insights into the future of manufacturing and digitalisation", says Sprich. Together with experts and application engineers , the Head of Sales will be present on all four days of the trade fair, located at stand B02, Hall 3.2 of the BERNEXPO exhibition centre.

ToolNews has been in touch with those in charge so that you know what there is to look forward to in Bern. Here are the topics that are not to be missed.

Digitalisation and Smart Factory:

The Hive Digital Suite

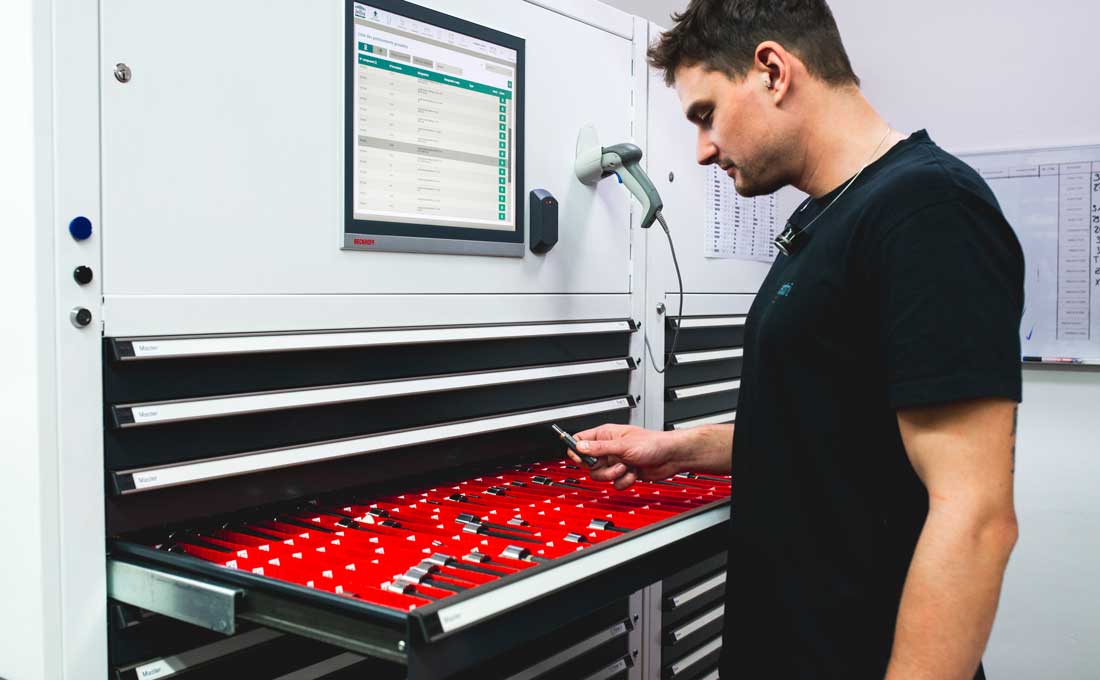

The future of production is digital. A key element for all companies that want to make their production smarter and more efficient is the Hive Digital Suite. The solution bundles together data from machines, tools, measuring equipment and purchasing and transforms it into value-generating information — specially optimised for Swiss SMEs.

From management of tools and measuring equipment with Hive Inventory to error-free series production with Hive Closed Loop Manufacturing, these solutions show how digitalisation really works. Our tip: Don't miss out on the live demos!

Production:

A new approach to precision and efficiency

Experience the future of production first hand: The aim here is to reduce processing times and process costs, to increase service life and process reliability and to make optimal use of existing production capacities. Our experts will demonstrate this through an optimised production of a hydraulic coupling and show how closed-loop applications are revolutionising production processes.

Measurement technology:

Faster. More precise. Better.

Because precision is the foundation of production: Our measurement technology highlights include over 40,000 items to overcome any challenge. From the versatile ConturoMatic to the ultra-fast SYLVAC SCAN — here quality is not just measured, but raised to a new level. We also have something special in store for Bern when it comes to 3D measurements: the portable TRIMOS measuring arm. A must-have for quality control.

Assembly and maintenance:

Innovative order

Manual and electric tools, modular acoustic systems, and innovative shadow boards ensure greater efficiency and productivity in the workshop. A special highlight is the TwistPro spiral vending machine, which makes consumables available at any time.

Comfort & ergonomics:

Relief for everyday work

Ergonomie endet nicht bei der Werkstatteinrichtung – auch Ihre Füsse verdienen Komfort. Mit den ATLAS® FIT Insole Einlegesohlen sorgen Sie für spürbare Entlastung bei jedem Schritt. Wir passen die Sohlen direkt vor Ort individuell an Ihren Fuss an.

That's why INNOTEQ 2025 is not to be missed

Those in charge agree: The trade fair offers the perfect opportunity to experience the innovations of Brütsch/Rüegger Tools live, be inspired and exchange ideas with experts. We will introduce you to new ideas and approaches that will drive your business forward.

Visit us in Bern and discover how Brütsch/Rüegger Tools can take your production to the next level. We look forward to seeing you!

Save the date: 11 to 14 March 2025, INNOTEQ Bern, stand B02, Hall 3.2 of the BERNEXPO exhibition centre.

Secure your free ticket with this code: 1801263084. You can find more exciting information on our trade fair landing page – HERE.