Introductory seminar on measurement technology 2025: Hands-on experience to shape the future

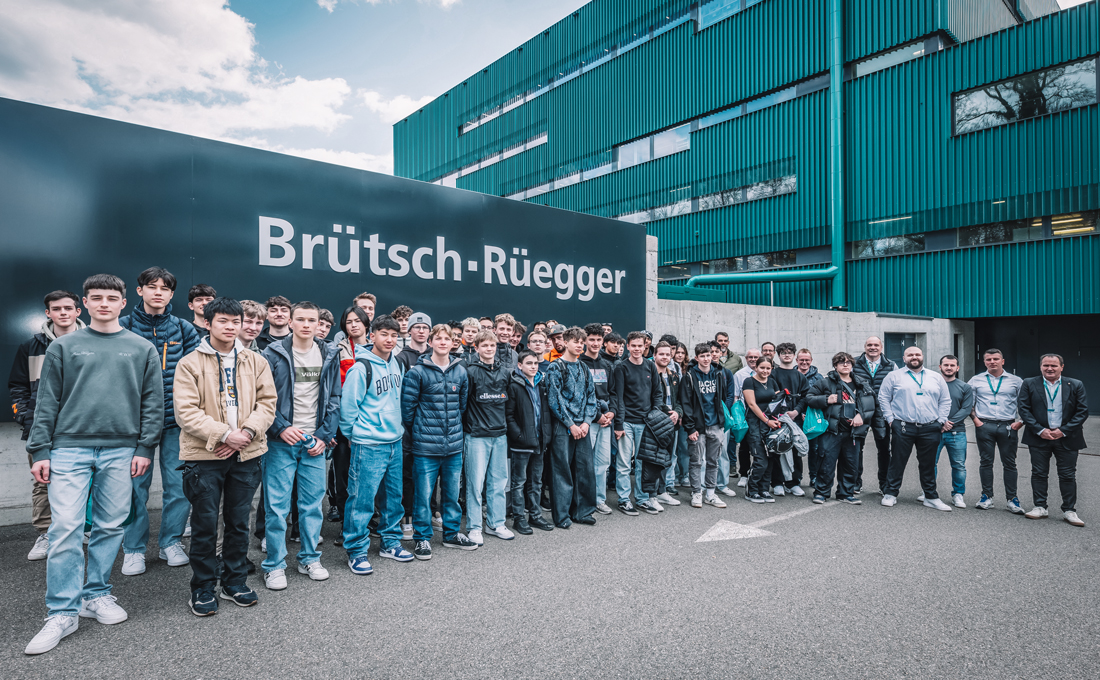

At Brütsch/Rüegger Tools, 45 vocational trainees experience the fascination of modern measurement technology up close.At the BWZ Rapperswil-Jona occupational training centre, tomorrow's technical specialists are trained in professions such as polymechanics, design/construction and plastics technology. On 31 March 2025, 45 vocational trainees were given the opportunity to deepen their theoretical knowledge within the company itself. Brütsch/Rüegger Tools opened its doors once again and allowed a unique look behind the scenes of modern measurement technology.

Full speed ahead with hands-on learning: Trainees at full throttle

After a warm reception with coffee and croissants, Stephan Allemann (specialist consultant) introduced the trainees to Brütsch/Rüegger Tools. They were then divided into five groups to experience five practical sessions. Experiences included using hand-held measuring instruments such as calliper gauges, viewing through microscopes, measuring with height gauges or roughness measuring instruments to experiencing the modern SmartFactory. The focus was a topic which is indispensable in industry: precise measurement technology.

Two topics were covered in the "testing and measuring room". Gëzim Uka (specialist in measurement technology) introduced the young people to height gauges from Trimos (V5 and V6). Peter Senn (specialist in measurement technology), with his 36 years of experience, explained the roughness measuring instruments from Mitutoyo (SJ-220), Mahr (PS-10) and Diavite (Micro). The trainees were able not only to get acquainted with the devices, but also to use them independently and make their first measurements on their own.

At the same time, under the guidance of Aleks Vukovic (specialist in measurement technology), the participants delved into the fascinating world of stereomicroscopes and looked at everyday objects with wide eyes. In addition, Stephan Allemann (specialist consultant) dealt with the topic of hand-held measuring instruments: Micrometers, calliper gauges, dial gauges etc. "Do you know the solution? Write it down. It's got to be exact", resounded from the large hall.

Hands-on high-tech

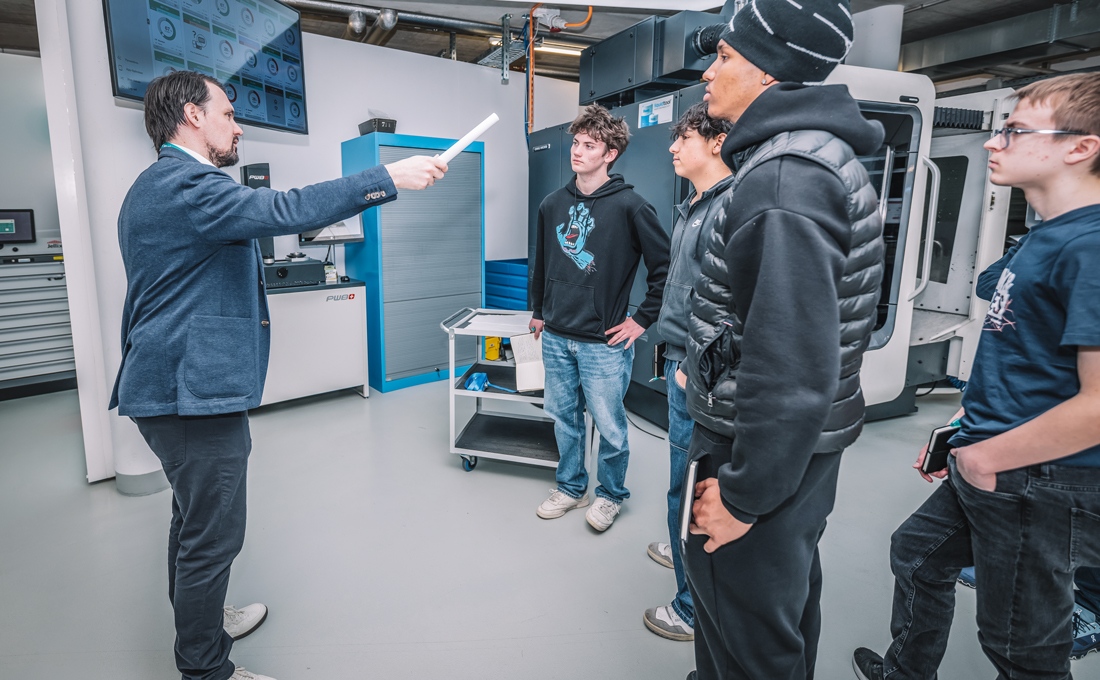

Another absolute highlight this year was the SmartFactory — something which the trainees all agreed on. The last two practical sessions took place in this impressive, futuristic environment. Marco Adank (consultant for industrial solutions) enthused the group with the highly digitised solutions around Quality Control / Hive Connect and modern ToolBoxes. Meanwhile, Christian Kipfer (specialist in measurement technology) really wowed the participants with his presentation of the SYLVAC SCAN S25T and the SYLVAC VISIO V3. The opportunity to work with these high-precision technologies themselves generated clearly visible enthusiasm among the trainees. Everybody had the same thing on their mind:

"It's amazing what you can achieve these days with digitisation — it's hard to imagine how it was done in the past".

At the SmartFactory, the future already feels within reach. Marco Adank (picture left) demonstrated the possibilities of the Quality Control / Hive Connect measurement software, while only a few metres away, high-precision 3D scans were carried out.

Putting knowledge to the test and winning

And suddenly it became very quiet in the room. The time had come: The big quiz at the end of a long day full of experiences was ready to get underway. 11 questions spanning all five practical sessions needed to be answered correctly. The goal was simple: Punch the exact answer into your phone in as short a time as possible. After just under 15 minutes, the winner was crowned with 10,126 out of 11,000 possible points — to the sound of roaring applause. Thanks to the support of partners Mitutoyo, Mahr, Sylvac, TESA, Energizer and Brütsch/Rüegger Tools, there were some top-quality prizes and gifts to be awarded. Everyone who took part also received an official certificate of participation.

Stephan Allemann summed up the day aptly: "The youth are important to our industry".

With this hands-on event, Brütsch/Rüegger Tools and its partners make a valuable contribution to the promotion of young talent and support them on their way into the industry of tomorrow.