Burckhardt Compression – A company applying all the right pressure

Compressors: A fundamental part of the future of energy

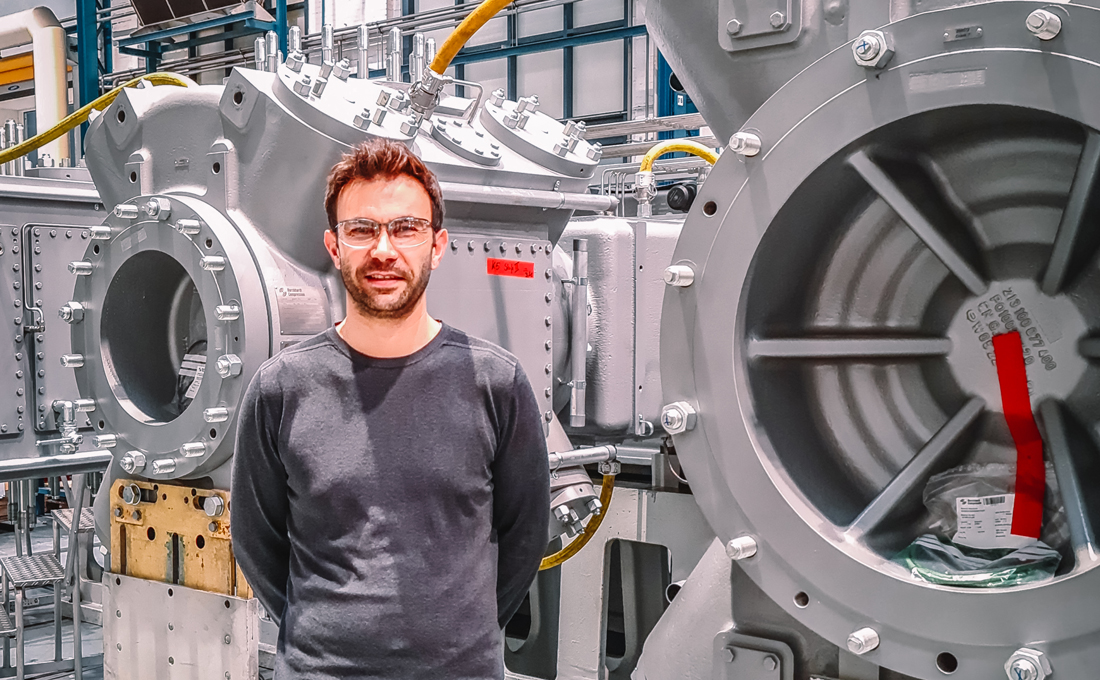

Sometimes you just need pressure. This is precisely what Burckhardt Compression is good at: "When it comes to compressor solutions on a large industrial scale, we are the first port of call," explains André Schneider, Head of Assembly at Burckhardt Compression. The large compressors produced in Winterthur and the company's other sites around the world are made in enormous dimensions. To put this into perspective: "On average, our plants range from 100 to 150 tonnes in weight," adds André Schneider. The compressors are used in various industries, with the gas industry being one of the biggest customers. These Swiss systems are used, among other things, for filling gas tanks, but Burckhardt compressors are also used in global shipping.

About Burckhardt Compression

Burckhardt Compression is based in Winterthur, Zurich, where the company plans and builds compressor solutions that are helping to build the future of sustainable energy and ensure the long-term success of its customers. The bespoke, modularised compressor systems are used in the chemical and petrochemical sectors, for gas transport and storage, in hydrogen mobility and energy, in the industrial gas sector and in refineries, gas production and gas processing plants. Recently, the company's focus has increasingly shifted to the energy sector, where it is actively driving forward the transition to renewable energy.

The production and storage of hydrogen is a comparatively new area of application. It is a segment that will becoming increasingly important for Burckhardt Compression in the future, as André Schneider explains: "The importance of renewable energies is always growing, which is why hydrogen, a sustainable fuel, is becoming increasingly relevant." The focus of Burckhardt Compression is also changing as a result of this strong social shift: "Renewable energies are becoming more and more of a focus for us."

Technology boosts human expertise

But how is the company making sure that this strategic realignment will succeed? "A key element of this lies in improving our processes," continues André Schneider. Tools such as the lean management approach and the opportunities provided by digitalisation can help to optimise production times and material flows. The latter is particularly important, as some segments continue to suffer from a shortage of materials.

"We therefore take great care to ensure that we always have the required materials available at the right time."

– André SchneiderThe shortage of skilled workers in various industries is also affecting Burckhardt Compression. This is because there is high demand for technical and mechanical specialists. While, for example, automation solutions such as industrial robots or a state-of-the-art 3D scanner can be used for prefabrication, a lot of manual work is still required for final assembly tasks. "Firstly, this is due to the dimensions of our systems and secondly, the fact that we manufacture our compressors to meet customers' precise requirements," explains Schneider.

Fortunately, Burckhardt Compression has a significant advantage in its efforts to win over young talent: Namely, the fact that their compressors will play an increasingly important role in the energy sector of the future. "As I said, we are active in the hydrogen production sector, but we also have a strong presence in the solar industry," Schneider continues. A special plastic is now used to protect solar panels. Compressors that deliver a pressure of up to 3500 bar are required to produce it. "We are one of the few suppliers who can build the necessary compressors." Being able to have such a direct effect on the future of sustainable energy makes Burckhardt Compression attractive to young professionals.

Burckhardt Compression has always relied on tools from Brütsch/Rüegger Tools for the numerous manual tasks required in the final assembly process. Not only does the company appreciate the small tools and measuring equipment themselves, but it also loves the simple ordering process and the ability to create bespoke tool storage. "This fits in perfectly with the lean approach we have adopted."