Masters of prototyping

The Sabato Group's production plant in "Watch Valley" near Biel differ significantly from other sectors of industry. You will immediately notice the white, glossy floor and the bright daylight LEDs which produce 6000 lumens. "We have always tried to ensure that our workshops are absolutely unique," explains Arnaldo Boldini. He runs the family business with Mike and Marco Sabato. "And since our staff are among the top specialists in their field, we provide a high-quality infrastructure to match."

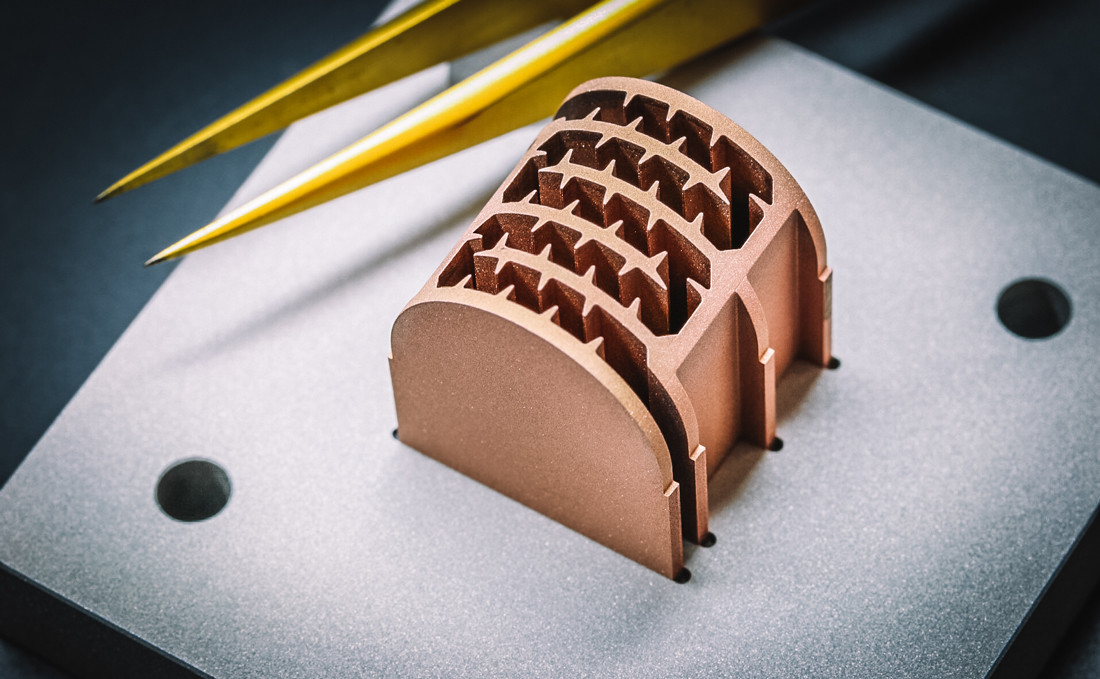

The high standards of precision, quality and aesthetics are the common thread throughout the culture and history of the Sabato Group. "We mainly manufacture prototypes for the watch and medical technology industries," explains Marco Sabato. "And these two sectors require the very pinnacle of accuracy." But at the Sabato Group, people are not content with simply adhering to specified dimensions and in fact every prototype that leaves the company has such a clean finish that you cannot see how it was made. The slogan "Precision. Quality. Aesthetics" can therefore also be regarded as a promise of quality.

Sabato Group

The Sabato Group's history dates back to 1980, when Luigi Sabato opened a small workshop, which traded under the name "Sabato Präzisionsmechanik" from 1989. The company focus at the time was on the production of precision mechanical parts. Exactly ten years later, his son Mike joined the company and its name was changed to "Sabato Mikrotechnik". In 2004, his brother Marco also joined. They continue to manage Sabato Microtec, growing the business all the time. In 2022, its new subsidiary "Sabato Lasertec AG" opened for business and now constitutes the Sabato Group along with "Sabato Microtec AG".

A proven approach

Obviously, going this extra mile in the finishing process is not strictly necessary. "The fact that we do it is a symbol of our own pride in our work," adds Marco Sabato. They treat every manufactured component as if it were a piece of jewellery. This added value in quality and care has always been part of Mike Sabato's philosophy. "And we continue to operate in this spirit."

And the company cannot complain about a lack of demand or growth, as quite the opposite is true. Fortunately, the extra work can be covered by the excellent workforce, according to Arnaldo Boldini. This also applies to the newly founded "Sabato Lasertec AG", whose innovative laser technologies will open up completely new possibilities for Sabato Group customers. The precision lasers can be used to machine sapphires, ceramics and diamonds, for example.

Trust is tool number one

The company does not accept any compromises with regard to the tools it uses. The Sabato Group has always relied on Brütsch/Rüegger Tools as a partner to maintain its enormously high-quality standards. They focus not only on the quality of the goods, but in particular on a constructive, partnership-based working relationship: "Our contact Carlo Ariu is often at our plant and is now so well-informed about our work that he can provide us with first-class solutions for our portfolio," explains Arnaldo Boldini. In addition, Brütsch/Rüegger Tools is always committed to supplying solutions that really help the Sabato Group to move forwards. "They don't just try to sell us the latest product, they recommend solutions that really fit in with what we do."

For more information, see: www.sabatogroup.ch