Quality to meet even the highest demands

To ensure quality, Richard Mille uses video measurement systems, which were supplied and installed by Brütsch/Rüegger ToolsThe name Richard Mille is almost synonymous with exclusive, high-quality watches with a distinctive design. These sophisticated timepieces are developed and produced in Les Breuleux, Switzerland.

To ensure the uncompromising quality required in luxury markets, the company uses a range of tools, including four SYLVAC VISIO V3 ❯ optical video measuring systems.

These systems were supplied and installed by Brütsch/Rüegger Tools, based in Urdorf, Switzerland.

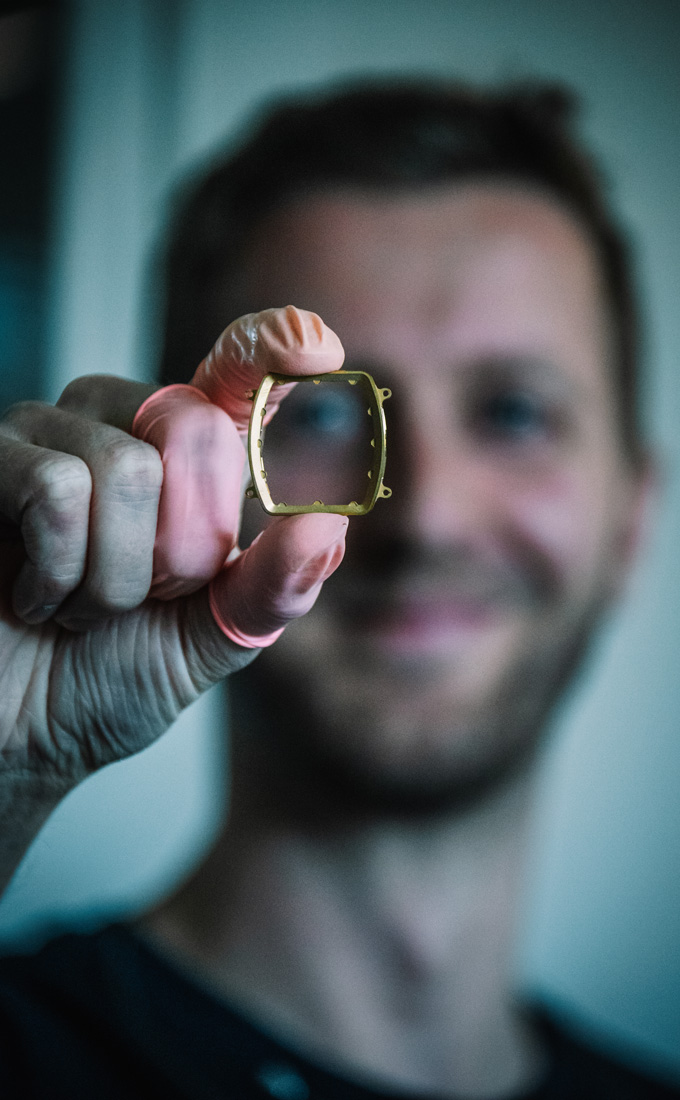

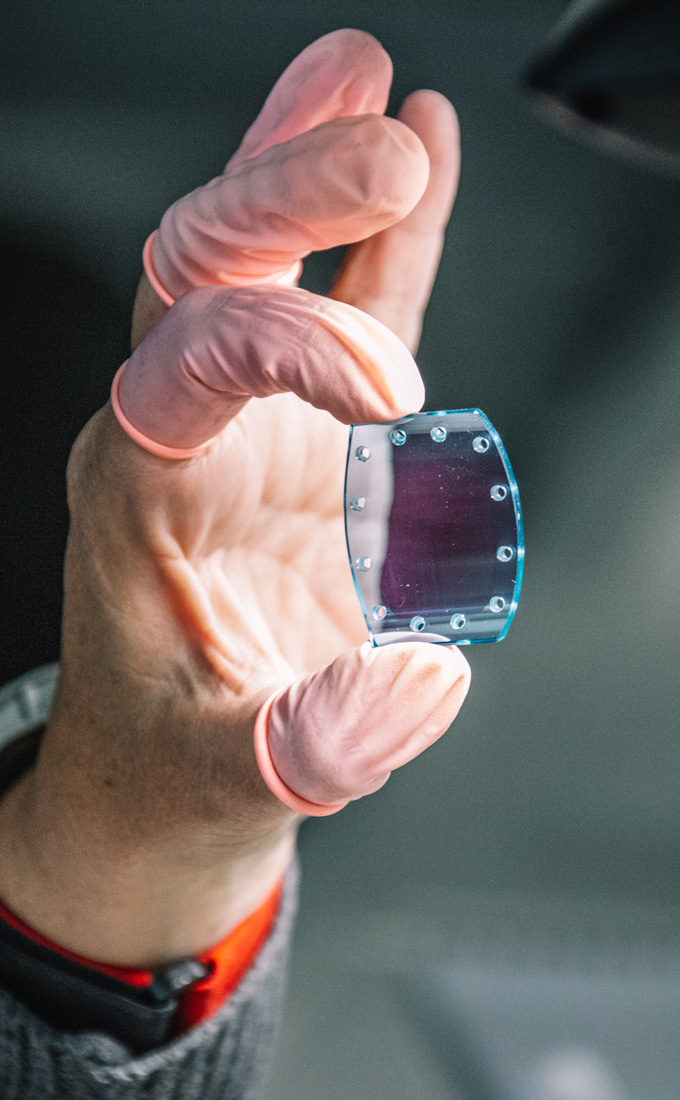

Exacting requirements and perfection are the guiding principles at Richard Mille. Ensuring the highest level of precision and quality during all production stages is therefore extremely important. Producing a Richard Mille watch is an elaborate process using materials and cutting-edge technologies such as those used in aviation, Formula 1 and high-performance sailing.

Most watch components are manufactured in-house by the company's own production departments, using a range of materials including Carbon TPT, Quartz TPT, titanium, ceramic, sapphire and gold.

You can also take advantage of the benefits brought by SYLVAC VISIO V3 video measuring systems:

- Non-contact component measurement and testing

- FULL HD camera, three different LED lighting options

- Simple testing procedures for improved efficiency

- Suitable for flat and turned parts

- Comprehensive quality assurance with automatic functions

- Save measurement results to create reliable documentation

Training in the use of this measuring device is required to ensure that it is used efficiently and safely from the start. For further technical information, please request a consultation.

Contact us at sales@brw.ch

Find out more about the SYLVAC VISIO optical video measuring systems here ❱

A high-performance system for a wide range of applications

At Richard Mille, the four SYLVAC VISIO 200 ❯ systems are used in three different areas. "During production, we prefer attributive testing, i.e. testing using comparison. The VISIO 200 is highly efficient in this respect," reports Eva Gallissot. With just one click, the system detects even minimal deviations between the actual and desired condition. The systems play a more varied role in the testing workshops, as here the measuring functions are also used.

"Casing" quality control is the department where all of the SYLVAC VISIO 200 ❯ features are used to their full potential, as the system can be programmed to automatically execute testing procedures. This enables processes to be planned with efficiency in mind, which also reduces the amount of effort and time required.

At Richard Mille, the use of video measuring systems complements other quality assurance procedures to ensure a better overview. "It's a competitively priced solution that offers high-quality optics, good image resolution, appropriate lighting and simple operation," explains Eva Gallissot.

Smooth installation

When making the decision to use Sylvac products, Richard Mille had three must-have criteria: Competitiveness, quality and using local suppliers. The system was installed and commissioned without any major issues: There was a problem with the software, but this was quickly resolved thanks to the professional support supplied by Brütsch/Rüegger Tools. Training staff on-site only took half a day.

A partnership many years in the making

Richard Mille has developed a loyal partnership with Brütsch/Rüegger Tools that has blossomed over several years. The watch manufacturer was impressed by the extensive range of tools, personal protective equipment and measurement technology available from Brütsch/Rüegger Tools, as well as flexible and efficient options for order processing and delivery.

A positive verdict

At Richard Mille, the verdict about the partnership with Brütsch/Rüegger Tools is extremely positive. "Of course, we will continue to work together," says Eva Gallissot, adding: "Brütsch/Rüegger Tools has also created a catalogue specifically for the watch industry ❯, which is of great interest to our company."

About the Richard Mille brand

Richard Mille only began producing watches in 2001, but even within this very short period, the brand has managed to climb to the very pinnacle of the Swiss watchmaking industry.

The company's roots actually date back to 1900, when Ali Guenat became the owner of a small watchmaking business based in Les Breuleux. This was the founding of the Guenat family business, which has been in existence for four generations.

Ali Guenat's grandson, Dominique Guenat, joined Richard Mille in 1999 and together they founded Horométrie SA in 2001. This company continues to be responsible for distributing Richard Mille watches produced by Guenat SA Montres Valgine.

Richard Mille has 39 watch stores located all over the world. Almost 54,000 watches have been produced over a period of 20 years.