Lean management and digitalisation — A dream team

The current economic barometer from the Swissmechanic Association gives little reason to celebrate: In the mechanical, electrical and metal industry, growth is steadily slowing down and key trading partners are becoming weaker. Nevertheless, 30 percent of Swiss industrial and manufacturing companies plan to increase their capacities this year. This raises the question of how this can be achieved without having to invest in expensive new plants or additional personnel. "Lean management is the answer", explains Reto Gruber, Specialist in this area at Brütsch/Rüegger Tools.

What exactly is meant by lean management, and how can industrial and manufacturing companies benefit from it? Lean management is a proven management approach for increasing efficiency and reducing waste during production. Brütsch/Rüegger Tools applies this principle within its own organisation and also provides advice and support in this area. "We offer SMEs holistic, pragmatic lean management advice from a single source", explains Reto Gruber. In this way, the leading Swiss tool partner enables its customers to streamline their production processes, minimise downtime and thereby reduce costs.

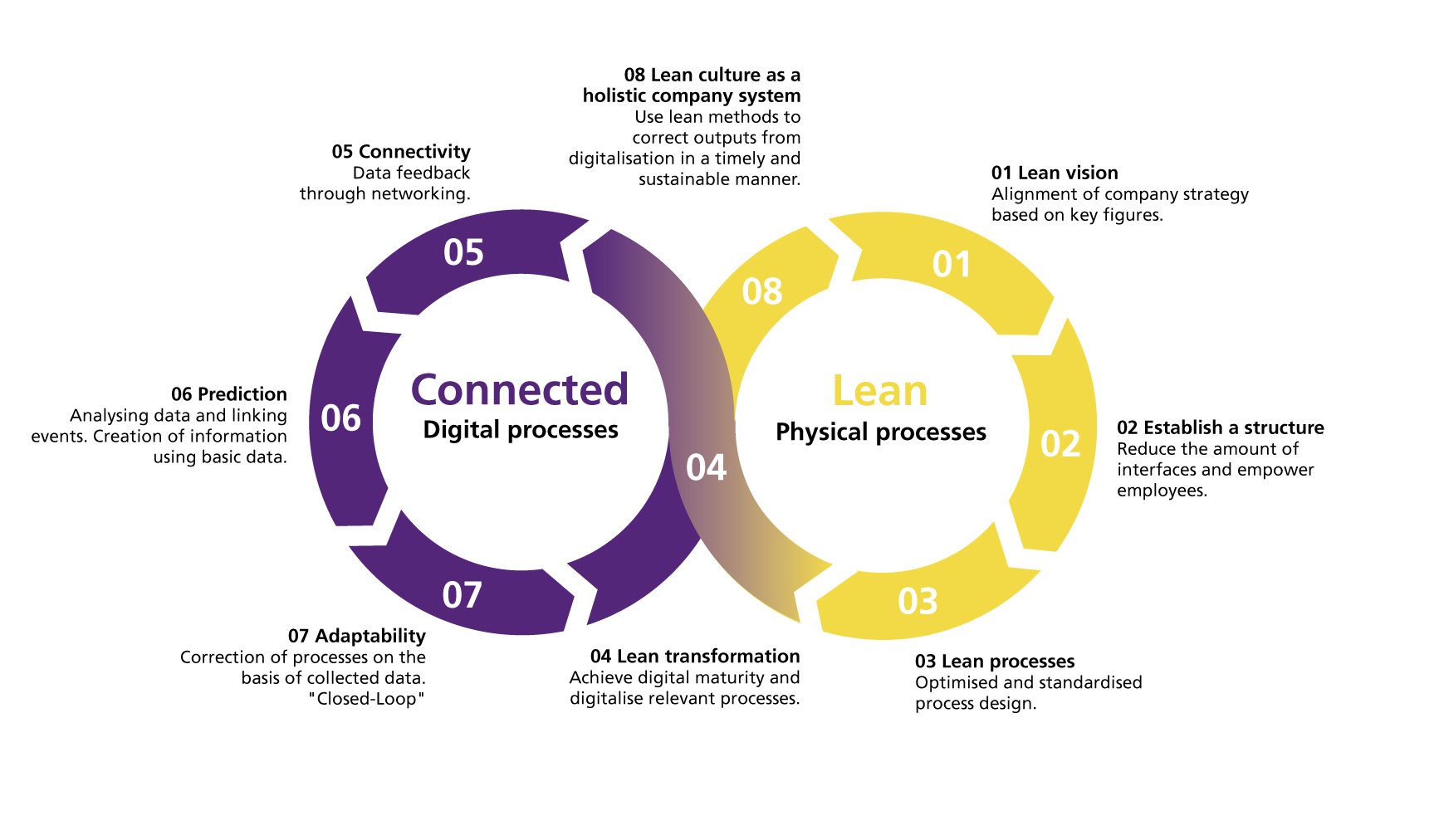

Lean management and digitalisation are two business disciplines which, when combined, can unleash their full potential and fundamentally transform companies. Lean management, which is based on optimising production processes, aims to minimise waste and maximise efficiency. Digitalisation, in turn, refers to the integration of digital technologies into all business areas, leading to fundamental changes in the way that companies operate and create value for their customers. Brütsch/Rüegger Tools boasts experienced experts and proven solutions in both of these areas, which can help you to identify and take advantage of these opportunities.

Digitalisation solutions: The future of production

Implementing the lean management approach is a crucial step towards more competitive and "leaner" operation. This potential can be expanded even further with appropriate digitalisation efforts: Brütsch/Rüegger Tools has recognised that the introduction of digitalisation solutions is the key to creating new capacities. "By integrating digital technologies into production, companies can optimise their processes and achieve greater production performance", explains Raphaël Müller, Head of Industrial Solutions at Brütsch/Rüegger Tools.

Raphaël Müller and his team offer a wide range of digitalisation solutions, including the implementation of IoT solutions, the introduction of automated production processes and the use of data analytics to increase transparency and production efficiency. In this way, for example, processes can be mapped clearly and digitally, new procedures can be tested and workflows can be visualised. What's more, companies can continuously monitor their operations and react quickly to any disruptions in the machine fleet — or even take preventive measures. Such digitalisation solutions enable companies to expand their production capacities with little investment in new machines. In other words: Lean management and digitalisation are two pieces of a puzzle that, when fitted together, open up completely new opportunities.

Digitalisation and lean management complement each other — bringing together what belongs together.

What sets Brütsch/Rüegger Tools apart from other providers is the holistic approach: The company offers its customers not only high-quality tools and products, but also comprehensive advice and support in the implementation of lean management principles and digitalisation solutions. Lean management is essential for effective digitalisation. And genuine added value from the data collected can only be obtained using the lean management methodology — thereby completing the circle. For example, in a digitalised manufacturing company, lean principles can be used to optimise management on the shop floor or to introduce further continuous improvement processes (CIP). "In this way, we create a holistic, technology- and data-driven lean culture that constantly refines and optimises the business processes", says Reto Gruber. The combination of lean management and digitalisation makes the difference between whether an SME is aligned with modern customer needs — or not.