The perfect measuring instrument for every application

Your partner for precise measurement — both manual and digitalAt first glance, the freshly milled metal part looks flawless. But as the saying goes, trust but verify. This is especially true for companies in the manufacturing industry as every component and every part that leaves their production plants must satisfy the very highest precision requirements. "This is why measurement technology plays a central role at manufacturing companies," says Peter Senn, a specialist in measurement technology at Brütsch/Rüegger Tools.

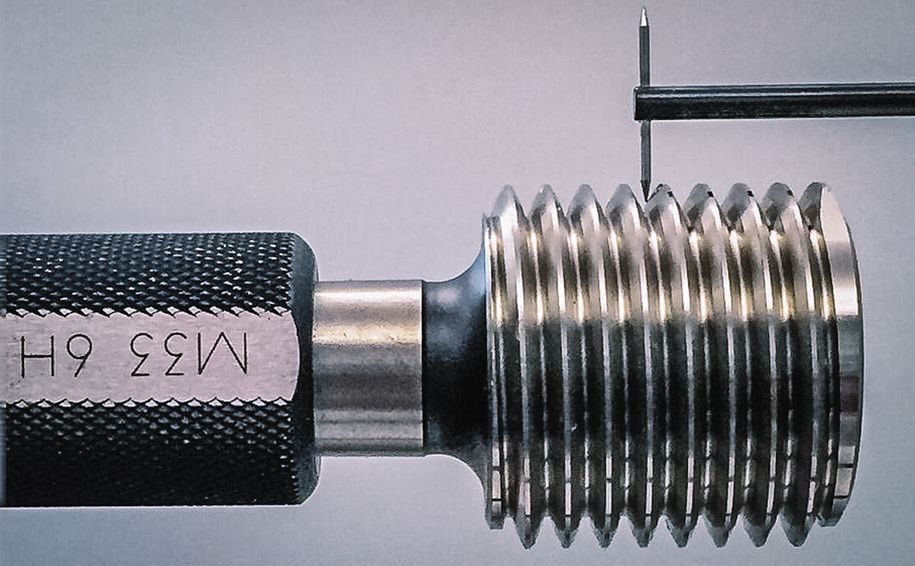

The level of precision required is perfectly illustrated by the aforementioned metal part: Companies in the metal industry must manufacture their products to an accuracy of 1.1 micrometres. One micrometre equals one thousandth of a millimetre. As a comparison, a human hair has a diameter of about 50 to 70 micrometres. "We are talking about an extremely high level of accuracy, which requires advanced measurement technology," says Senn.

If you need precise measurements, you've come to the right place

Accuracy and speed are the main quality features that describe the Measurement Technology department at Brütsch/Rüegger Tools. As the leading Swiss tool partner, the company provides a comprehensive range of measurement solutions. The product range covers everything from physical and optical measuring instruments to horizontal and vertical measuring tools and complex 3D coordinate measuring devices. This ensures that production companies of all sizes and in all sectors will find the perfect solution for them. And thanks to agile logistics, rapid delivery is guaranteed. If you want to get an overview of the range yourself, you can pay a visit to the Brütsch/Rüegger Tools showroom in Urdorf, Zürich. You can also take a look at and try out all the state-of-the-art measuring instruments for yourself.

Spoilt for choice

Brütsch/Rüegger Tools offers a wide range of measuring tools, from simple calliper gauges to high-quality measuring microscopes and digital scanners. Its own brands FUTURO and NERIOX are synonymous with the very highest quality and value for money. The range includes a wide choice of products from the company's own brands. Together with other well-known brands such as Sylvac, TESA, Mitutoyo and more, we deliver maximum reliability and precision for measurement technology. We are happy to support our customers in selecting the most suitable measuring instrument for their needs.

We know that it is not always easy to find the perfect tool for your business from the wide range of options. Brütsch/Rüegger Tools therefore relies on personal conversations to identify the key criteria that are important for a company. That enables us to recommend the perfect products. Peter Senn draws on 34 years of experience in measurement technology to provide this advice.

Our customers benefit not only from our expertise in choosing the right measurement technology, but also from the support of our specialists on site. For example, these specialists carry out maintenance on the systems and help to ensure that objects are clamped correctly. "In addition, the correct calibration of the measuring equipment on site is an important part of our comprehensive customer service," explains Senn. And in the event that a measuring instrument needs to be replaced or repaired, a loan unit will be provided to the companies concerned until it can be returned.

The future of measurement is digital

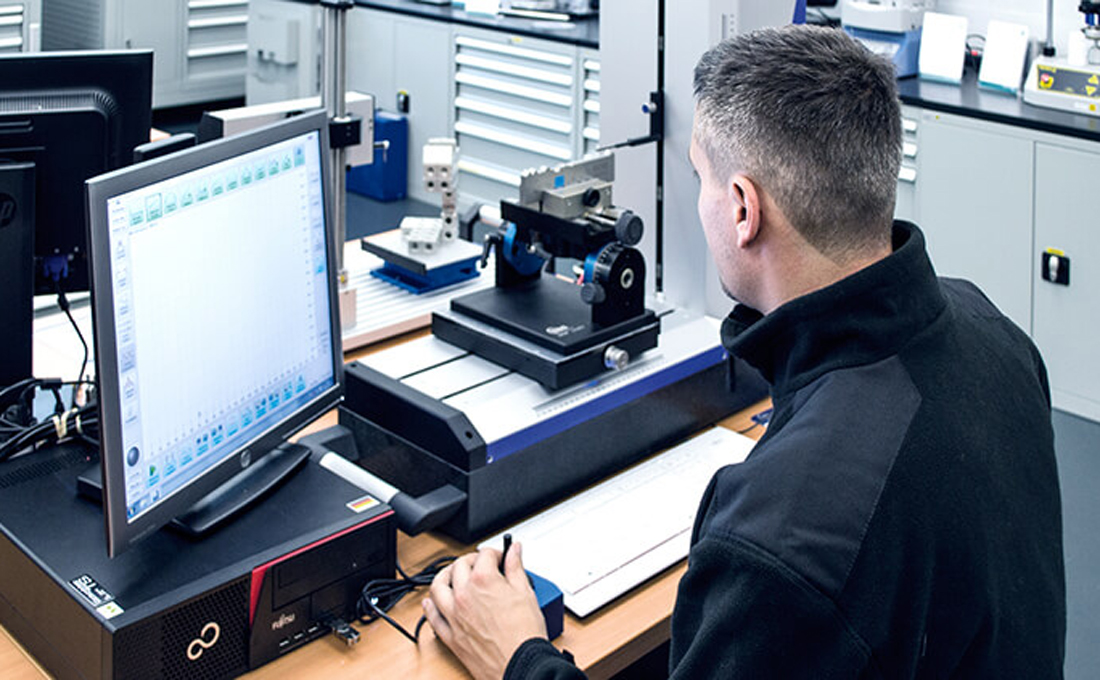

In addition to the wide range of products and close customer support, the Measurement Technology department at Brütsch/Rüegger Tools also boasts another important feature: It helps companies to digitalise their measurement tasks and make these tasks much more efficient. The key to this is the Hive Digital Suite, the industrial automation solution from Brütsch/Rüegger Tools.

"This enables our customers to bring together all the raw data from machines, tools, measuring equipment, goods management and purchasing,"

explains Raphaël Müller, Head of Industrial Solutions at Brütsch/Rüegger Tools.

The Quality Control module plays a key role within the Hive Digital Suite. It supports personnel when measuring components and logging and evaluating data. This not only means that the final inspection of the manufactured parts is easy to carry out, but also that companies receive important insights into production while it is still ongoing (process measurement). Another advantage is that Quality Control can be displayed directly on a laptop or a touchscreen tablet on a tool table next to the machine with very little effort. This makes it very user friendly and no additional tasks result from the use of the digital solution.

With Hive Connect, the measuring equipment can even be integrated into the system digitally to enable the measurement data to be transferred and logged automatically. This is essential because compliance with measuring tolerances is often no longer guaranteed by the customer, who instead delegates this responsibility to the manufacturer. "This makes accurate logging even more important for every manufacturing company," explains Müller. Companies that still manually enter their measurement data in Excel lists are definitely approaching the limits of their systems in this regard. Thanks to the Hive Digital Suite and the Quality Control module, companies can successfully bridge the gap between production and final inspections. "And that is exactly what we mean by saying that we are helping our customers to take this step into the digital future.”

This short video gives a good insight into the functionality of the Quality Control module.