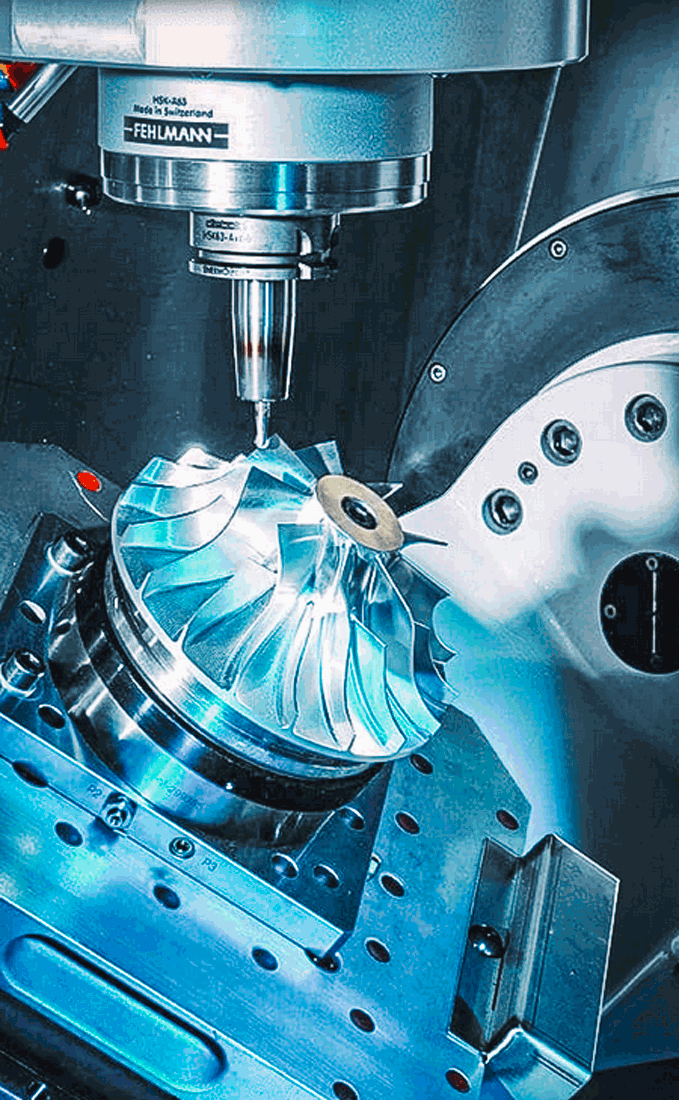

Contract production: Precision "made to order"

The industry's extended workbench

In the world of precision parts, every detail is crucial. And it is in precisely this field that Robert Ott AG has made a name for itself. Founded in 1989, the company based in Seon, Aargau is a contract manufacturer for the machining industry and specialises in precision parts for sectors that maintain the highest standards: "Our customers include companies in the MedTech and semiconductor industries," explains sales director Raphael Rudolf. But what makes Robert Ott AG such a sought-after partner for these companies?

Many Swiss companies no longer manufacture their own products in-house. "For these companies, our contract production offers an attractive solution," says Rudolf. Instead of having to move their production abroad, they can outsource parts of the manufacturing process to specialists here and therefore benefit from short travel distances, a common language and culture as well as the highest quality.

From single parts to the finished assembly...

Seon sees itself as an extended workbench for its customers. The company not only offers precise manufacturing of mechanical components, but also covers the entire process chain. "We can offer both upstream and downstream steps, such as heat and surface treatment." This enables individual responses to customer requirements and offers everything from a single source, from individual parts to the finished assembly.

But Robert Ott AG offers more than just this wide range of options — it also has an extensive client portfolio: The contract manufacturer relies on diversification to avoid the risk of production bottlenecks. "This allows us to maintain our agility and stay relatively resistant to market changes," explains Rudolf. This also requires readiness within the company in terms of continuous development. They believe that a company should not rely on what has been achieved and rest on its laurels, but instead must be consciously open to new things. This forward-looking approach has driven the company, and in particular Raphael Rudolf's sales team, to continuously acquire new and demanding projects.

Lack of skilled workers? There's no point complaining!

The shortage of skilled workers is a pervasive problem in industry and the manufacturing sector. However, the contract manufacturer isn't going to complain about it — instead, it is taking action. The company runs its own training centre and trains six apprentices in polymechanics and production mechanics per training year. Its aim is to integrate young talent into the company as early as possible and to show them the diversity of this professional field. To this end, the company also relies on an attractive and varied working environment and a range of tasks in order to keep motivation high. For its more than 165 customers, each with their own drawings and demands, flexibility is essential.

Here, Robert Ott AG also benefits from the fact that its sales are set up in a specific way. "Because we are not typical salespeople," explains Raphael Rudolf. The entire sales team consists of trained polymechanics. This background enables them to understand the technical needs of customers from the ground up and to quickly offer tailor-made solutions. “Often, it is not just about price, but also about recognising and meeting the customer's specific needs.”

A clean job for the highest demands

Cleanliness is of the utmost importance, especially in the MedTech and semiconductor industries. Impurities caused by particles or germs can impact the function of components and systems. In order to meet these enormously high demands, an investment has been made in the form of a cleaning cell of ISO class 7. This "clean room" ensures that sensitive parts are cleaned and packaged under controlled conditions.

In addition to cleanliness, precision and measurement accuracy play a key role in quality assurance. Robert Ott AG uses state-of-the-art measuring instruments that ensure precise testing of the precision parts. This is the realm of Head of Measurement Technology David Saner. "It goes without saying that all components, parts or subassemblies match the exact specifications," he emphasises. To ensure the precision required, we rely on measuring instruments from Brütsch/Rüegger Tools, including the ConturoMatic TS system. "Since we manufacture a very wide array of parts, it is a challenge to ensure that they conform to the drawings that the customers provide. We also need to be able to detect roughness and measure threads, so we need have complete reliance on our measuring equipment." The fact that Brütsch/Rüegger Tools provides first-class contact and offers the space to look at the devices before you decide to buy is an enormous benefit here. Various hand tools are also purchased from its partner in Urdorf.