How movement and precision are combined

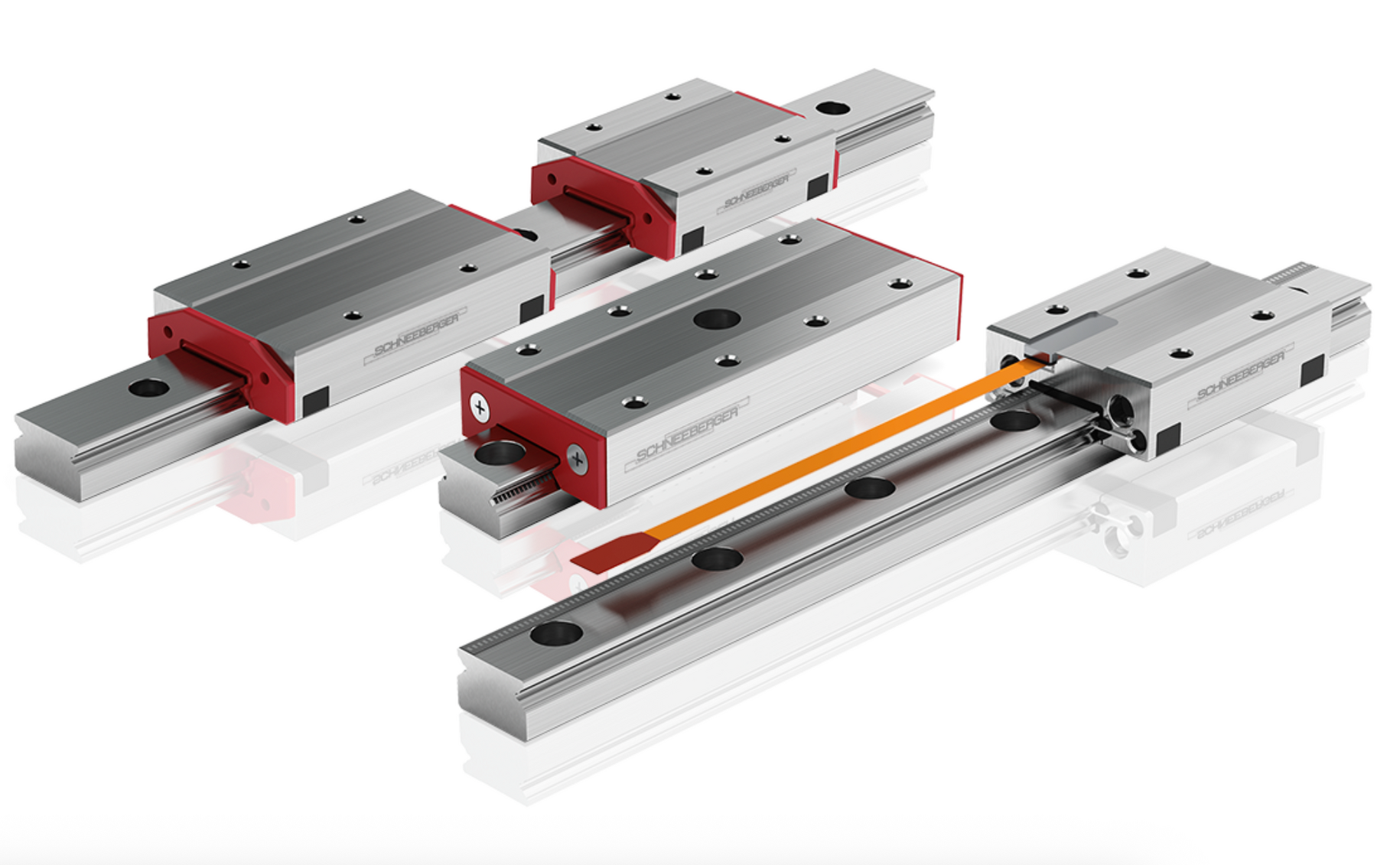

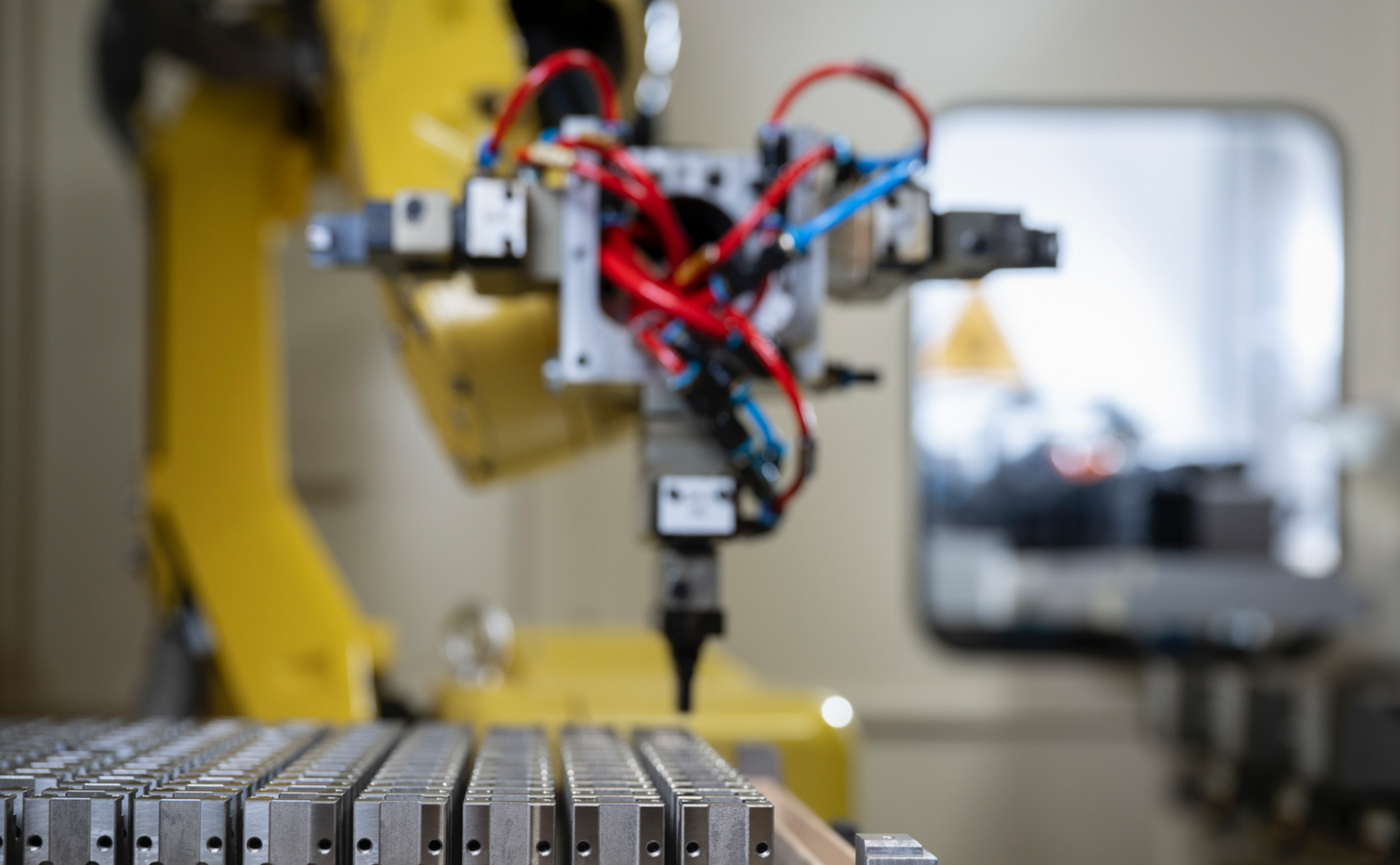

The term "linear technology" may raise questions when you first hear it. But Moritz Vogler, Vice President of the Minirail division at Schneeberger, describes the company's specialty quite simply: "Just imagine a drawer that can be moved back and forth along two guide rails on an axis." The guides that Schneeberger manufactures for industry are basically comparable to this – except that they are, of course, much more precise and designed for much higher loads. This art of high-precision linear motion forms the foundation of the Schneeberger company, whose product range extends from large profile rail guides and complex positioning systems to mineral cast beds and miniature guides, which can be equipped with integrated absolute or incremental measuring systems on request.

The latter are mainly used in medical technology, semiconductor manufacturing, and measurement technology. Here, the focus is not on moving heavy loads, but on maximum precision, high repeatability, and reliability in the most confined spaces. Schneeberger's mini rails and slides with integrated measuring systems are designed precisely for this purpose.

The values of a family business

The basis for success is a unique corporate culture: Schneeberger operates as a family business that consistently focuses on the long term. This is reflected in a spirit of innovation that is not swayed by short-term market cycles. "If we are convinced of a product idea, we stick to it." This confidence in its own innovative strength, coupled with an unwavering focus on quality, customer proximity, and delivery reliability, is the company's recipe for success.

These proven strengths are also being drawn upon in the current times, which are extremely turbulent for many industries. Instead of pausing, Schneeberger is pursuing a countercyclical strategy. The opening of a third plant in Roggwil is a clear commitment to Switzerland as a location and to growth – and also sends a signal of confidence in the future. "We are preparing for the upturn, because it is coming," emphasizes the Vice President with conviction. These phases of change are currently being used as an opportunity to develop new products, strategically expand the portfolio, critically examine internal processes, and try out new things that would not be possible under full load.

It fits in with Schneeberger's innovative mindset that two "TwistPro" spiral machines from Brütsch/Rüegger Tools are in use. Thanks to smart software, these machines support all kinds of businesses in goods and tool management and can dispense gloves or safety goggles around the clock, among other things. This makes companies more agile, saves money, and increases their occupational safety.

Would you like to find out more?

You can find all the information here.