SIAMS 2026: We are exhibiting – Tools. Next Level.

The trade fair for the entire microtechnology production chain

From April 21–24, 2026, you can find us in Hall 1.2, Booth C18/E13. As a multi-brand supplier, Brütsch/Rüegger Tools presents a comprehensive range of products for the micromechanics and watchmaking industries. Increase your productivity and expand your capacity with the power of your data and our Hive Digital Suite applications.

Our young and dynamic team looks forward to discussing the current challenges facing the industry with you and sharing our vision for an intelligent and environmentally friendly future.

We look forward to seeing you there!

Our key topics:

The Hive Digital Suite, consisting of several modules, combines raw data from machines, tools, measuring equipment, goods management and purchasing and transforms it into value-generating information. Hive Digital Suite — optimised for Swiss SMEs.

Vending spiral machine:

100% availability around the clock and full cost control. Suitable for tools, consumables, PPE, hygiene items and much more.

For customers in the watchmaking industry and micromechanics, we have developed an exclusive tooling range with over 10,000 items from around 220 manufacturers, complemented by comprehensive advisory and service offerings.

The best brands for the watchmaking industry

Uncompromising efficiency: our tools and equipment meet the highest professional requirements – maximum precision, proven robustness and excellent value for money.

Dynamic measurement: Sylvac Scan S25T

Equipped with the latest technology, this high-resolution, highly accurate measuring device is ideal for fast inspection of small cylindrical parts up to 26 mm in diameter and 200 mm in length, e.g. watch components, dental implants or bone screws.

- Simple, intuitive operation

- More than 150 measuring functions

- Fast, accurate, non-contact

2D video measurement: Sylvac Visio

Using the video measuring microscope, various geometric shapes, features and dimensions are automatically measured within seconds via 2D profile projection, for example on watch plates.

- Transmitted, coaxial and incident illumination

- Short training time: max. half a day

Reducing machining times and process costs, increasing tool life and process reliability, and making optimal use of existing production capacity: that is the clearly defined goal of our application specialists.

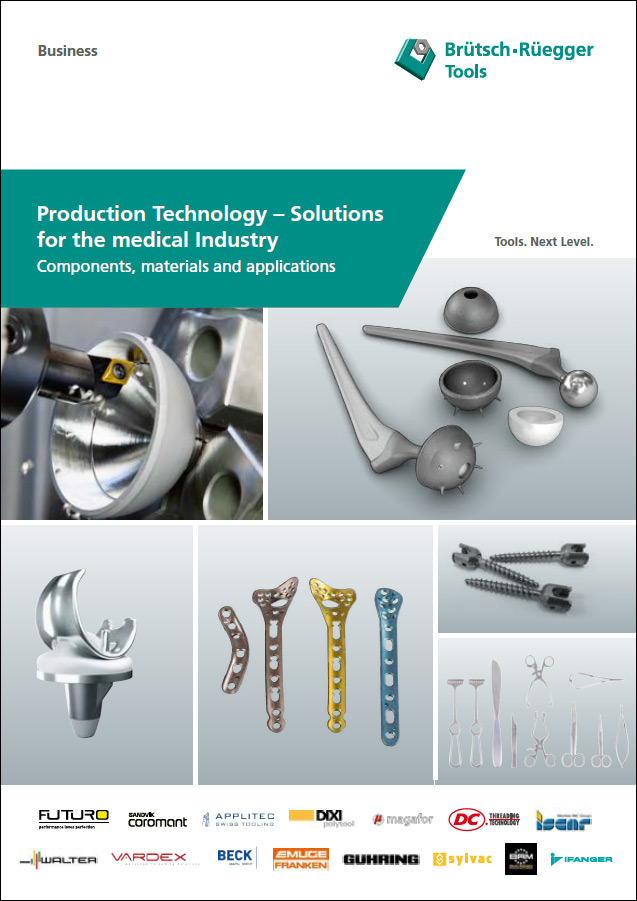

Manufacturing solutions for MedTech components

From implants to surgical instruments – every component places the highest demands on material, machining and precision.

Best-of-breed solutions for the complete manufacturing process of medical implants and instruments.

Maximum precision. Innovative machining. Perfect surfaces.

Maximum dimensional accuracy, state-of-the-art machining technologies and flawless surfaces – for the precise manufacturing of the finest watch components.

Hand and power tools from A to Z. Also workshop equipment, complete workshop maintenance and small machines.