Metron: Uncompromising quality to ensure customer satisfaction

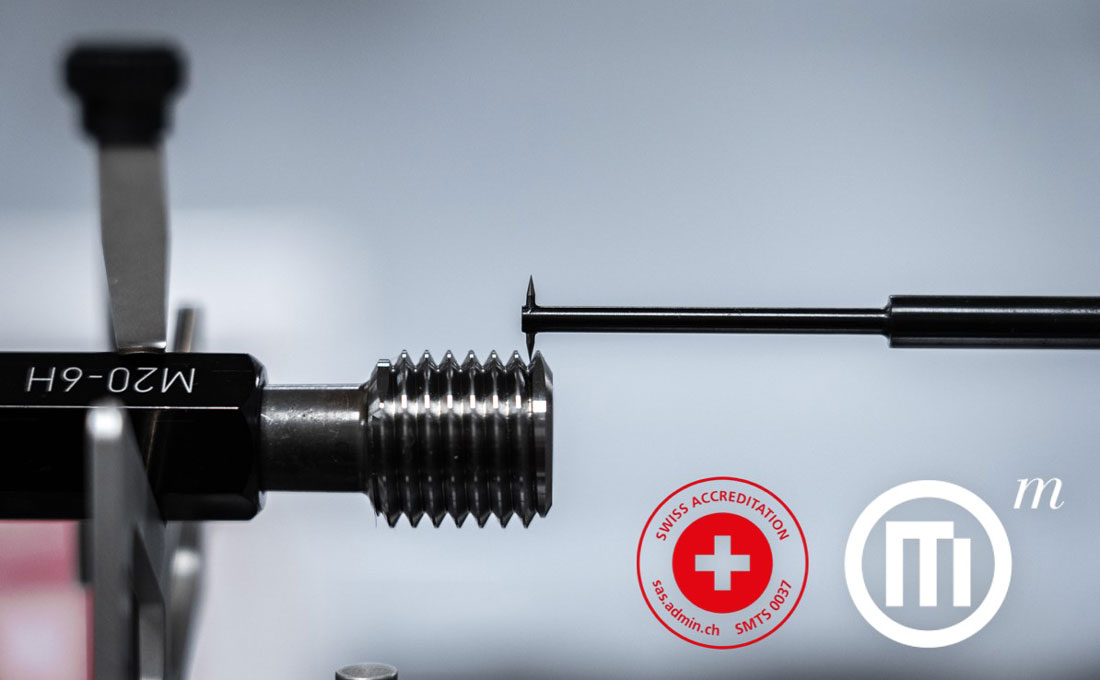

Successful completion of the calibration project for M1 thread ring gauges: Brütsch/Rüegger Tools supplied and installed a ConturoMatic TS-X contour measuring instrument for Metron Measurement SA to enable maximum precision and efficiency.

“The Measure of Measure” is the motto of Metron Measurement SA. Based in Quartino, the company is one of the leading SCS-accredited laboratories in Switzerland and strives for the highest level of quality in calibration and metrology services. Metron continuously improves its quality system and the expertise of its technicians in order to meet the increasing demands of its customers. Regular investments ensure this high standard.

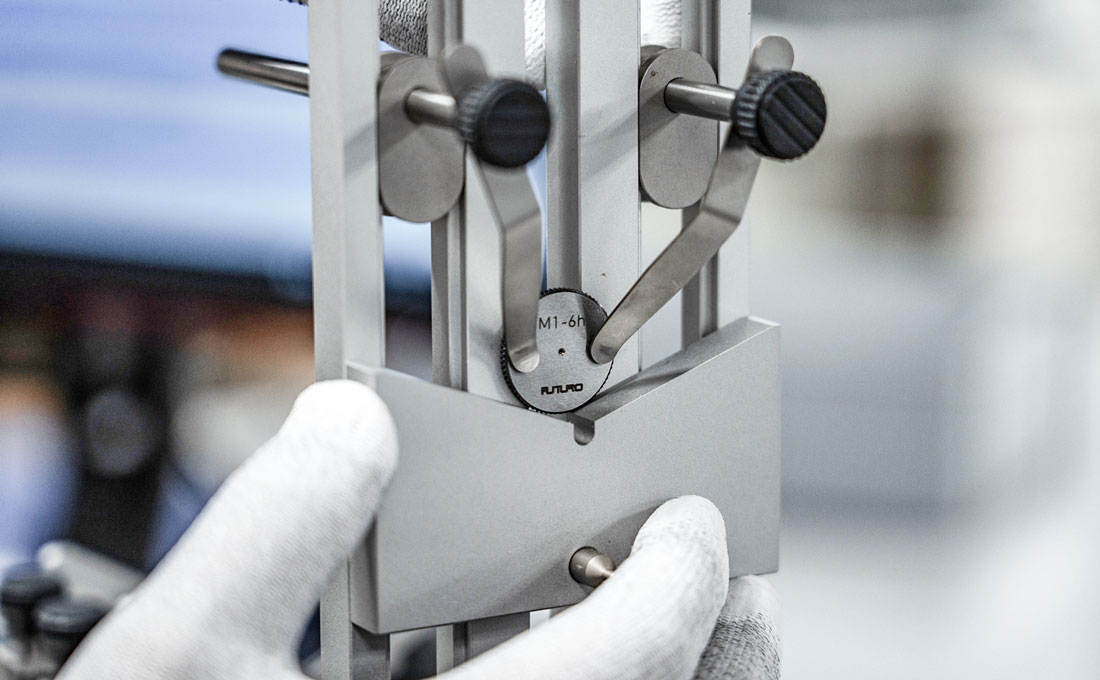

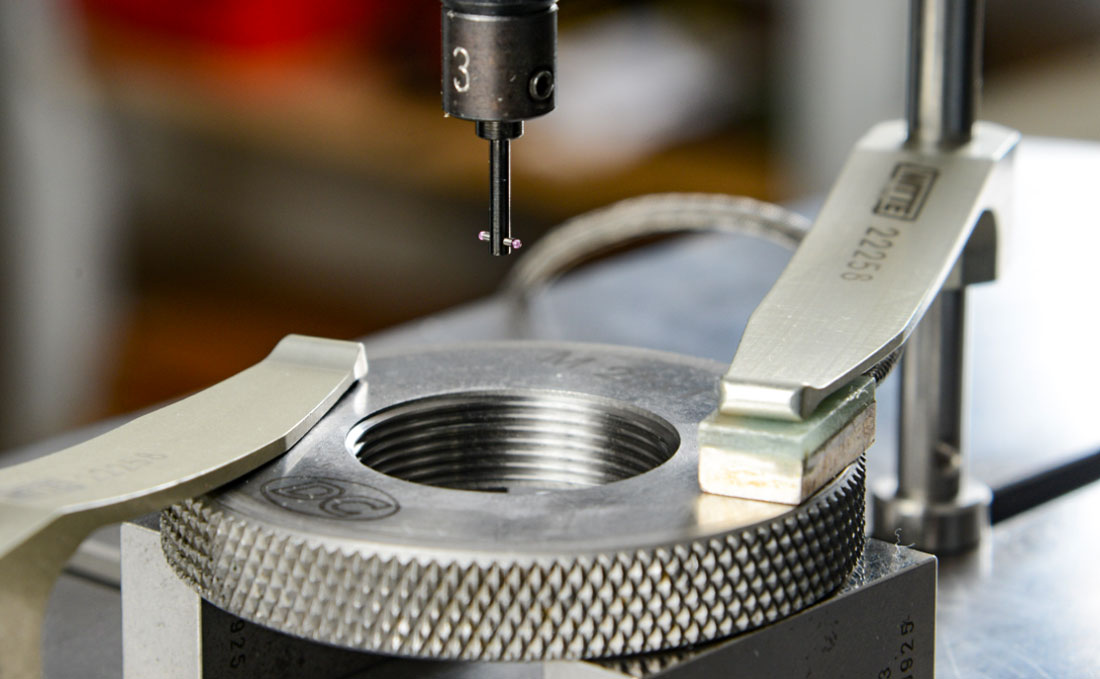

Metron uses the ConturoMatic TS-X contour measuring instrument with extended thread evaluation for the calibration of thread gauges. The device works using the profile method, records exact thread profiles and analyses them in accordance with standards in the test equipment software.

However, the scope of the ConturoMatic system goes beyond calibration: It is also used in manufacturing and quality assurance technology to test geometric shapes (angles, radii, distances, parallelism) and surface properties (roughness) of components.

Benefits of the ConturoMatic TS contour measuring instrument:

- Precise and versatile: Ideal for contour and profile measurements in quality assurance, watchmaking, medical technology and automotive engineering.

- Exact results: Measures external and internal contours with high repeatability.

- Maximum precision: Total error of +/- (0.85 + L/100) μm for the smallest tolerances.

- Technical highlights: Robust design, measuring range of 250 x 320 mm, granite guiding elements and motor-controlled X- and Z-axes.

Do you want a personal consultation? Feel free to contact us at sales@brw.ch

Increased precision and efficiency

"The new ConturoMatic system ensures the uncompromising quality demanded by our customers in the long-term and also helps us to increase the efficiency of our testing processes", explains Alessandro Capone, Business Administration & Laboratory Manager at Metron Measurement SA. With the implementation of this system, Metron Measurement SA is the first SCS-accredited test laboratory in Switzerland to offer precise calibration of thread ring gauges from an internal diameter of 1.0 mm.

"With the ConturoMatic, we can now meet the demands of customers in the watchmaking industry and medical technology sector, where the profile of the thread is just as important as the diameter", says Alessandro Capone. The new measuring instrument does not replace the previous method, but builds on this to enable an extended offering and attract new customers. Metron Measurement SA is currently the only laboratory in Switzerland that can offer SCS calibrations for small thread ring gauges from 1.0 mm, which represents a major competitive advantage. Moreover, the introduction of the ConturoMatic TS-X has resulted in measurable improvements in productivity and competitiveness, and has positioned Metron Measurement SA as a leading company in the field of precision calibration.

New customers as a result of SCS-certified calibrations

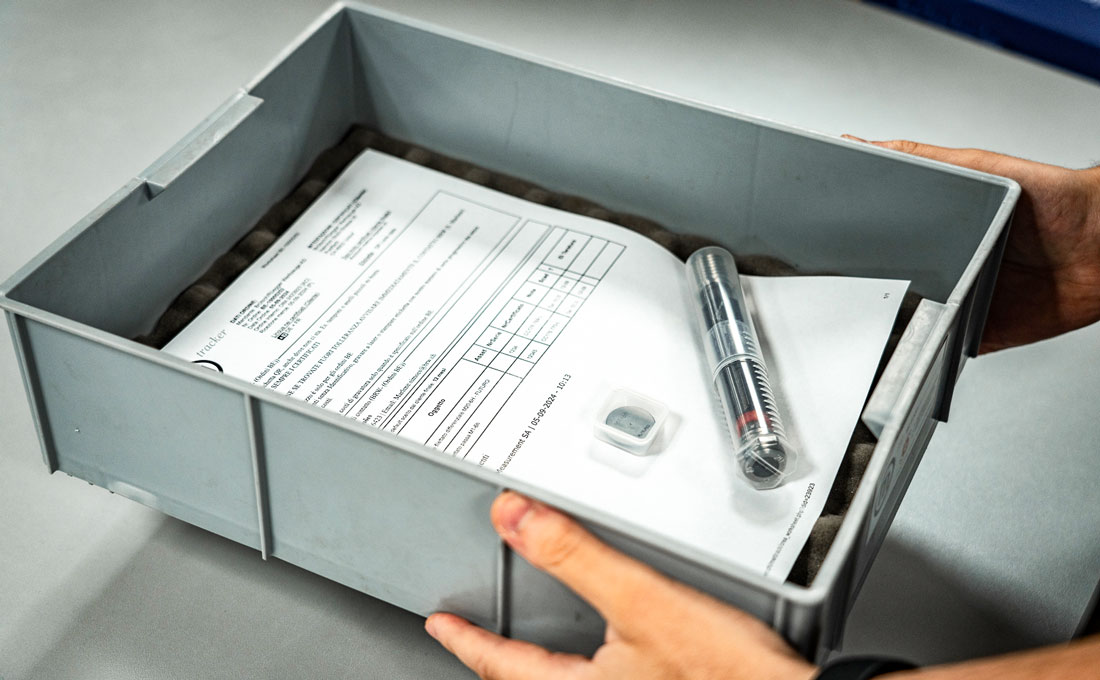

Together with the commissioning of the new measuring instrument, the testing process was also certified by the Swiss Accreditation Service (SAS). Issuing SCS certificates for calibrations allows new customers to be won. Certified calibrations are becoming increasingly necessary with continuously growing demands for traceable quality and traceability of measurement results. In addition, the company was able to penetrate new markets that were previously inaccessible without certification.

Full support from Brütsch/Rüegger Tools

The decision in favour of the ConturoMatic was made due to the achievable precision compared to other contour measuring instruments. "Reliability and the ability to perform complex in-house calibrations also played an important role. This has enabled us to shorten lead times and increase overall productivity", reports Alessandro Capone. The contour measuring instrument has fully met expectations and is firmly integrated into the calibration process. Customers benefit from increased precision and shorter lead times.

The modern measuring instrument was supplied and installed by Brütsch/Rüegger Tools, based in Urdorf, Switzerland. "Before that, extensive preliminary work and intensive tests were carried out", reports Marco Suter, Service Technician Measurement Technology at Brütsch/Rüegger Tools. "Our specialists collaborated closely with Metron Measurement SA to provide the optimal solution." As a result, a system was installed with various options precisely configured to meet demands. "It is not an 'off-the-shelf' product, but is individually adapted to the needs of the customer", explains Marco Suter.

Conclusion: Optimally supported — From expertise to service

"The extensive experience of Brütsch/Rüegger Tools in installing and commissioning complex technical solutions was definitely a huge advantage in the smooth introduction of the new measuring instrument", says Alessandro Capone. All deadlines and specifications were achieved as agreed. Professional support was provided during the implementation phase through staff training sessions and comprehensive technical support.

Brütsch/Rüegger Tools offers a complete service package for contour measuring instruments in the ConturoMatic series, covering installation, commissioning and calibration through to user and advanced training sessions, software maintenance and technical support from specialists.

About Metron

Metron Measurement SA is an independent, SCS-accredited calibration laboratory for length, force, torque and electrical calibration. Metron is renowned for innovative solutions that help companies increase efficiency, reduce costs and decrease environmental impact.

The portfolio includes comprehensive calibration services for industrial customers, for example in medical technology, the pharmaceutical industry, mechanical engineering and the food industry.

The company offers both on-site and in-house calibrations, ensuring its customers meet quality standards and regulatory requirements.

Profile

- Established: 2005

- Location: Quartino, Switzerland

- Industry: Measurement technology

- Employees: 12

- Certification: ISO 17025:2017 and SN EN ISO/IEC 17025:2018

Laboratory

- Height: 206.41 m asl

- Local gravity: 9.806004 ± 0.000057 m/s²

- Latitude: 46° 09' 1.9"

- Longitude: 8° 54' 42.3"

- Atmospheric pressure: 0.98804 ± 0.00981 bar

Interested in Metron services? Visit the company's website at: metron-labo.ch