INNOTEQ 2025: We will be presenting — Tools. Next level.

The mechanical, electrical and metal industry, medical technology, the watchmaking industry and micromechanics all benefit from our expertise in machining, measurement technology and assembly — right up to digital solutions for greater transparency and efficiency. Visit us at stand B02 in Hall 3.2 and discover how we can take your production to the next level.

Use the code 1801263084 for a free ticket.

Our key topics at INNOTEQ 2025:

The Hive Digital Suite, consisting of several modules, combines raw data from machines, tools, measuring equipment, goods management and purchasing and transforms it into value-generating information. Hive Digital Suite — optimised for Swiss SMEs.

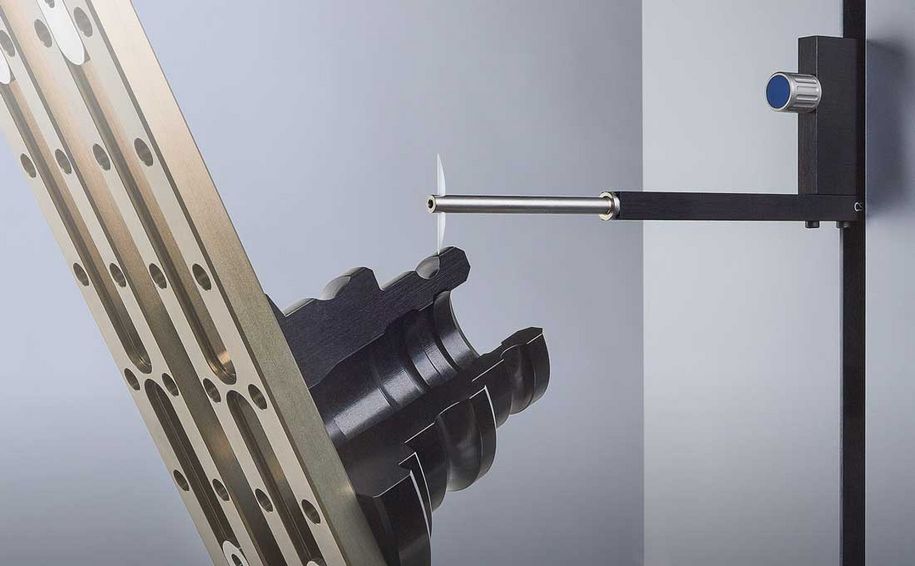

Reduce processing times and process costs, increase service life and process reliability, and make optimal use of existing production capacities. These are the goals declared by our application engineers.

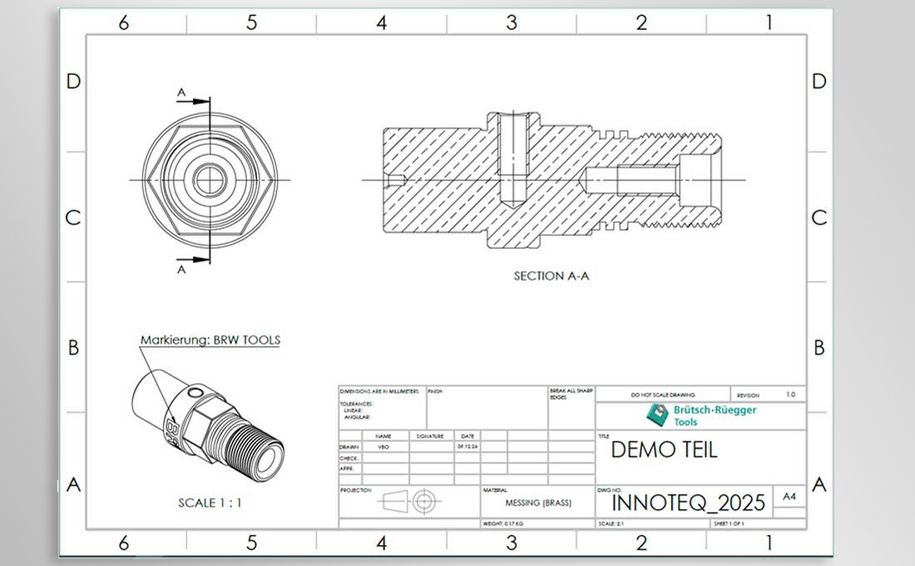

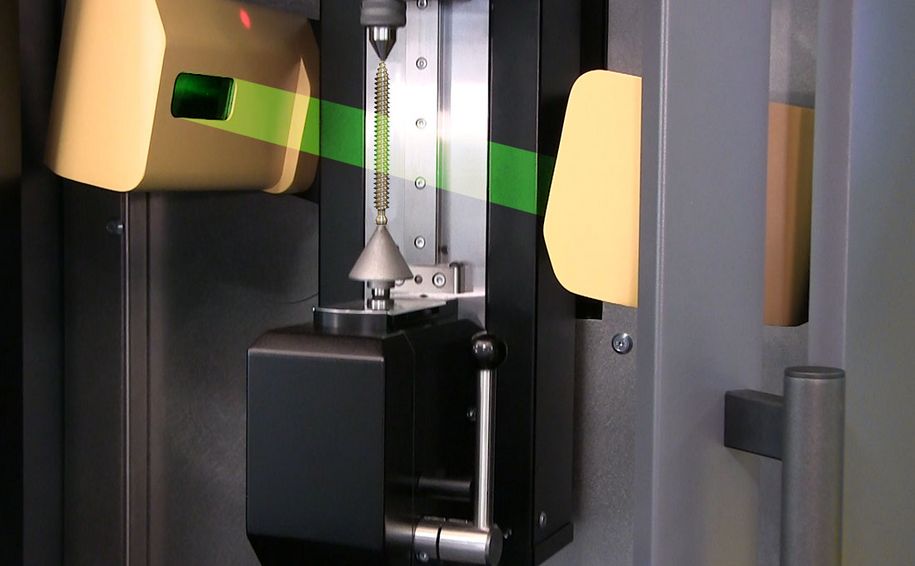

A comprehensive measurement technology range of over 40,000 products provides the optimal solution for every task.

In addition, high-quality height gauges, dial test indicators, roughness and force measuring instruments from leading manufacturers.

A full range of manual and electric tools as well as shop equipment and everything you need to keep your workshop functioning as it should, right down to small machines.

TwistPro spiral vending machine:

100% availability around the clock and complete cost control. Suitable for tools, consumables, personal protective equipment, hygiene items and more.

ATLAS® FIT INSOLE:

3D moulding for maximum adaptability. The core of the insole is heated and therefore adapted to the individual arch of the foot. Your very own footprint — walking and standing like you're on cloud nine.