Four tips for optimising your production processes

Brütsch/Rüegger Tools not only supplies tools, but also ensures that they can be put to optimal use. Our field-proven expertise helps you get the most out of your production environment.

Did you know that...

- reducing the tool price by 30% only reduces the unit costs by 1%?

- increasing the cutting data by 20% reduces unit costs by a massive 15%?

- machine hourly rates and labour costs make up the majority of the total costs?

The greatest potential savings in the production environment therefore lie in planning and designing the cutting processes. If you want higher productivity, greater process reliability and less wear, you should check your production environment from time to time.

Benefit from our free quick check

Would you like an independent opinion on particular processes in your production environment? Request our free quick check for dynamic milling (only german and french)

Our quick check for "dynamic milling" includes the following:

A) Logging the machining process at your premises

B) Analysing the milling processes and the components you manufacture

C) Analysing the tools and travel paths you use

D) Reprogramming and simulation by our application specialists at our SmartFactory

E) Running in the new process on the machine at your premises

It goes without saying that we tackle specific challenges and conduct data analysis using existing 3D models.

1. We master the 360-degree view

Taking a holistic view of production processes is standard procedure for us at Brütsch/Rüegger Tools. Our application specialists are trained in mechanics and have many years of experience. They are familiar with all types of machining processes and efficient strategies for five-axis machining, such as dynamic milling. Our experienced professionals analyse not only your tools and how you use them, but also your cutting data, the material you machine, your machinery and your component geometries — with the fundamental aim of enabling you to manufacture with greater speed and reliability yet lower wear. Our cost calculations include every single factor that affects the OEE.

2. We advise and support you on-site

If you want to make your machining even more cost-effective, you will almost certainly have to employ external consultants. Brütsch/Rüegger Tools is tackling this growing demand from manufacturing companies with its consultancy services. Our skilled application specialists visit your premises, analyse the situation and identify all potential areas for optimisation. This includes showing you the savings potential for your specific parts. We will ensure that you can meet the ever-increasing demands of the Swiss market.

Your benefits at a glance:

- Brand-neutral consultancy in tool selection

- Recommendations for making the best use of tools (e.g. based on cutting data and usage data)

- Lower process costs, shorter processing times, improved machining strategies, increased tool life and greater process reliability (e.g. for unmanned production)

- Shorter machining times, minimal clamping and reclamping operations and less clamping equipment

Have we piqued your interest? Contact your application specialist today at verkauf.fertigungstechnik@brw.ch!

3. We keep pace with innovation

If you want to reduce your throughput times, you need to be open to modernisation. because improving production processes is a continuous process. This is why we monitor the latest production trends very closely indeed. The fact that the emerging market of electromobility is shifting the sector's focus to the machining of aluminium alloys and glass fibre-reinforced plastics is just one of many examples. NB: We intend to unveil some exciting new products in this area very soon, so keep your eyes peeled!

4. We supply you with tool data for CAD/CAM programming

We have created a fantastic service to provide you with a solid foundation for digitalising your production processes: In the near future, we will be able to supply you with 2D and 3D tool data from all manufacturers, all from a single source as you would expect. In doing this, the Brütsch/Rüegger Tools machining team is proud to help you and all other customers take an important step toward Industry 4.0.

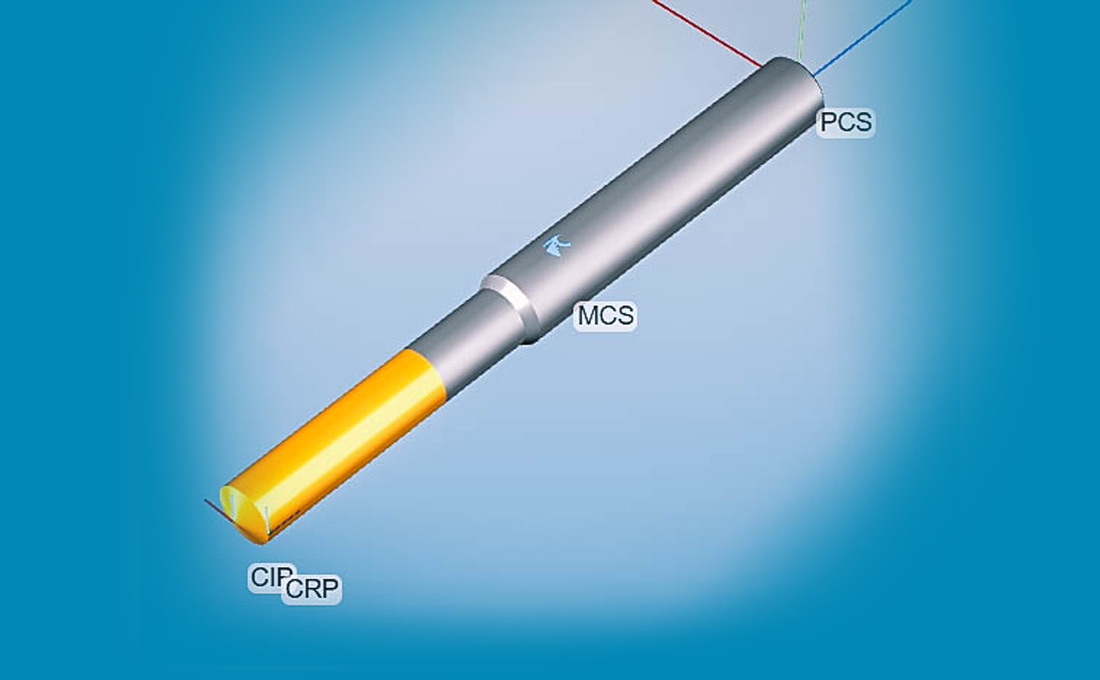

From spring this year, tool data for over 100,000 items will be available in the ToolShop — including those for our own popular brands FUTURO and NERIOX. All data is catalogued using DIN 4000-compliant special software. The big advantage of this is that your CAD/CAM software can use the data set to identify which part of the tool belongs to the cutting edge and which part belongs to the shaft, for example. This enables you to get started immediately and program and simulate processes quickly and easily.