Maag Pump Systems AG — exemplary operation for impeccable hygiene

By commissioning the TwistPro vending machine, Maag Pump Systems AG has once again proven itself to be a pioneer in the field of personal protective equipment. The efficient and networked vending machine offers every employee and visitor the right protective equipment as soon as they enter and works 24/7.

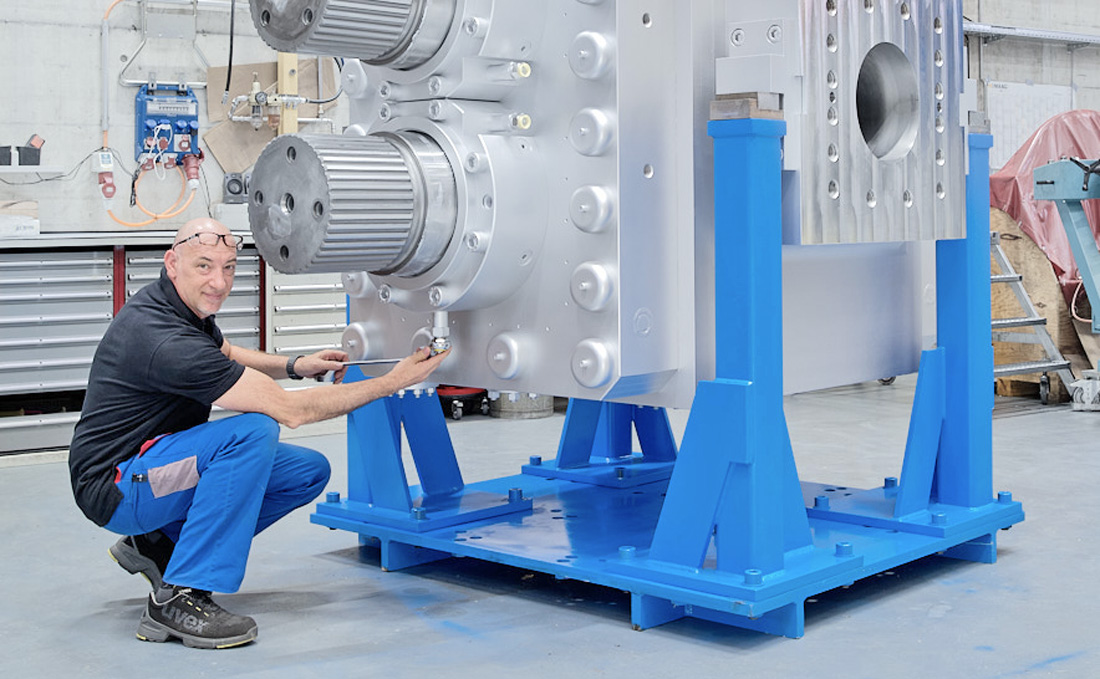

Maag Pump Systems AG has always attached great importance to high safety standards. The dimensions and loads of the gear pumps, some of which weigh several tonnes, require sophisticated protection concepts for the 150 or so employees at the Oberglatt site.

Protection against COVID-19 was likewise taken seriously early on. Right at the beginning of the first wave, new access controls were set up and a partner was sought to offer an efficient solution for managing protective equipment. Patrick Müller, Safety Officer at Maag Pump Systems, explains: "In three-shift operation, protective equipment such as face masks, disinfectants and safety goggles have to be made available without employees having to run across the building to the material dispensing point first."

Pump technology:

globally unique expertise

Maag Pump Systems AG develops and manufactures gear pumps for polymer production and processing. The focus is on continuously optimising enclosures, shafts, bearings and shaft seals. The company is based in the Swiss municipality of Oberglatt and employs around 150 people, boasting extensive expertise in the construction of large pumps.

The Maag Group is a business unit of Pumps & Process Solutions, a segment of Dover Corporation, which emerged as a pump technology product division from the former Maag gear factory in Zurich. The Maag Group is a globally active and broadly diversified solution provider with integrated and customisable process technology systems for the polymer, chemical and petrochemical industries.

Hygiene products available 24/7

Brütsch/Rüegger Tools installed the TwistPro spiral vending machine in the entrance area a short time later. This enables both employees in the workshop or offices and visitors to be supplied with hygiene products before they enter the building — 24 hours a day, 7 days a week.

Individually tailored to needs

Even after commissioning, the compartments can be easily adapted to meet specific needs. "The specialists at Brütsch/Rüegger Tools modified the TwistPro by adding several compartments for FFP2 masks. Within a short time, the spirals that deviated from the basic configuration were reequipped and electronically stored with the desired product," says Patrick Müller. "The system has more than proven its worth over the past year and will continue to be used for PPE in the future. There's nothing we can't keep in this as far as compact products are concerned."

Implementation in badge the reader system

In order to generate as little additional effort as possible, employees simply obtain their goods with the ID badge they already have. The administrators set individual rights and retrieval limits. What's more, if a customer is visiting, the employee who invited them can obtain protective equipment using their coffee badge too.

Automatic reordering for replenishment

The TwistPro makes managing protective equipment much faster, more orderly and less complicated. The networked logistics system decreases the effort required too: When the set minimum stock level is reached, the TwistPro automatically places an order for the relevant item. If this is done by 5 p.m., the goods will be delivered at the start of the next working day.

Patrick Müller is satisfied with the investment: "We appreciate working with a partner who, like us, always wants to get the best out of their systems. The TwistPro has clear limitations, but is still versatile enough to meet specific needs. Thanks to the spiral vending machine and having strict yet clear rules, we haven't had to restrict production since the beginning of the pandemic."

Would you like to install an efficient vending machine too? Our logistics solutions experts will be happy to advise you on +41 44 736 63 63 or at info@brw.ch.