Optimising production costs – where does it make sense?

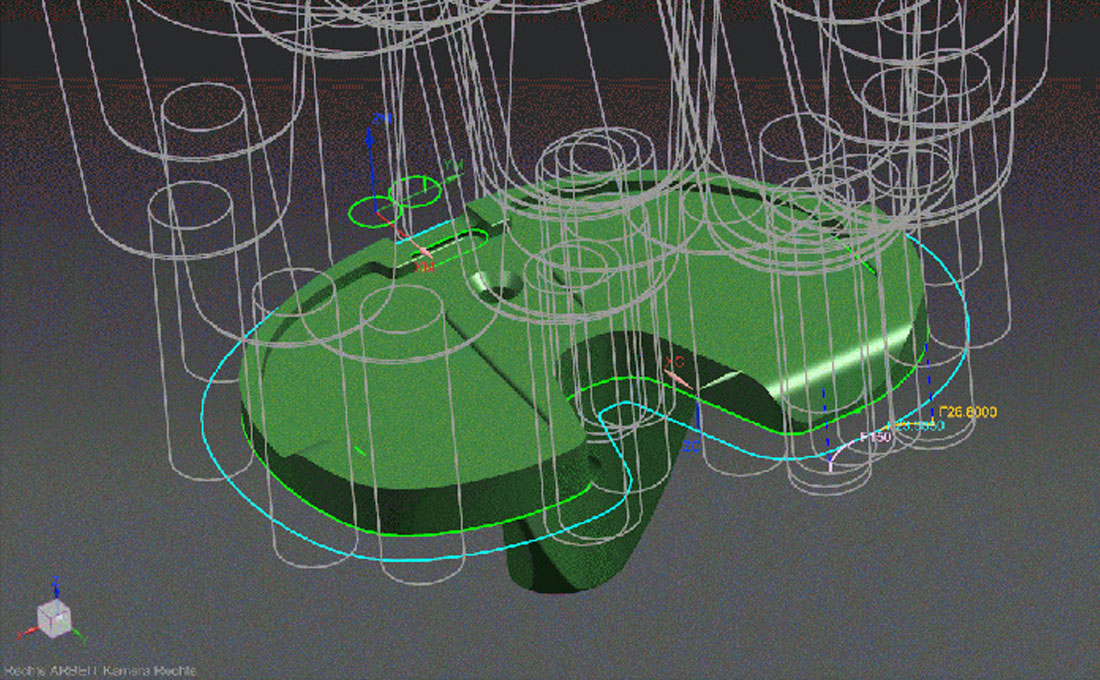

When it comes to reducing workpiece and overall costs, many people think of cross-sectional issues such as the flow of goods, co-ordination and efficiency. But within production companies, the greatest savings potential lies in the planning and design of machining processes. While the tools play a secondary role here, innovative strategies such as five-axis machining with circular segment cutters or dynamic milling harbour vast potential. And only modern processes can benefit from the actual strength of the tools.

Nevertheless, trochoidal milling, for example, where tool paths are optimised and processing time shortened using a CAM software, is still used relatively rarely. The same can be said for digital possibilities such as accessing process data on the shop floor. Anyone who wants to get a headstart is therefore testing machining processes and accelerating the digital transformation. From experience, Brütsch/Rüegger Tools knows that productivity, process reliability and quality can be increased within a short time, minimising wear and tear.

Thanks to modern production methods, production in high-wage countries is back in the competition. It's a trend that hasn't gone unnoticed by Mark Flommer, Head of the Business Unit for Production Technology at Brütsch/Rüegger Tools: "Tool and mould making is shifting back to Europe from Asia."

Meet Mark Flommer

Brütsch/Rüegger Tools is delighted to introduce Mark Flommer as our new Head of the Business Unit for Production Technology. As a trained industrial mechanic, the 48-year-old cut his teeth in machining early on and developed a great deal of expertise in this area, covering a range of different perspectives. The technical business graduate and federally certified industry master has assumed all kinds of tasks working for several well-known tool manufacturers, ranging from the construction of custom solid carbide tools and product management all the way to business development. Mark Flommer has a great deal of experience in machining and is well versed in the concerns of all the positions involved.

Our services: Focusing on your application

Brütsch/Rüegger Tools is the ideal partner for optimising milling, turning and drilling processes as well as planning and designing them. Our application specialists have many years of practical experience and support production companies, from consulting and individual tests to the implementation of modern milling strategies. We will analyse your machining processes on site, re-simulate them and provide you with an assessment. Or we can show you the new processes on our machine in our SmartFactory and accompany their introduction on your own machines. What's more, we are able to evaluate your entire production processes, including in our SmartFactory. "We show you the savings potential for your specific parts in real time," explains Mark Flommer. The most important information on our services can be found at the following link:

By the way: To get things off to a reliable start, Brütsch/Rüegger Tools offers a free "Quick Check" for dynamic milling, where your processes, procedures and tools are analysed (only available in German):

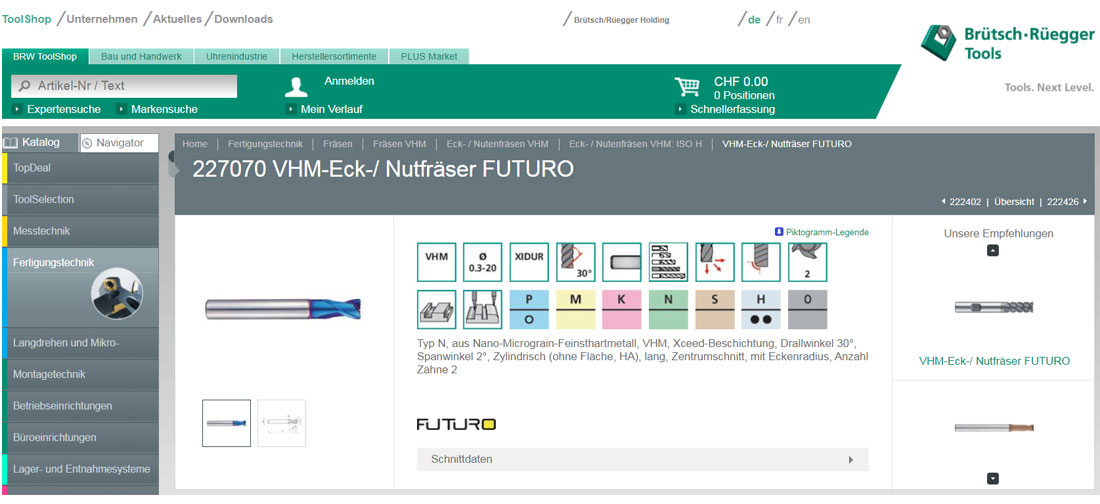

ToolShop: Optimised navigation

We too are constantly optimising our processes. Thanks to the new ToolShop structure with visual editing, you can get to your desired products more quickly and easily – focusing on your application and in a brand-neutral way. Thanks to pictograms of the various milling processes and ISO colour markings of the materials to be processed, navigation in the ToolShop is clearer and more user-friendly than ever. On the product pages, you will find all relevant information, such as about a tool and its application area, including the relevance for the individual materials at a glance. Non-metallic materials such as plastics are now also listed with ISO-O.

Full range for production

The proven full range and comprehensive services in production technology make Brütsch/Rüegger Tools the best possible production partner. Thanks to our top logistics, which have been perfected over the decades, customers who place an order by 17:00 (electronically until 17.30) receive their items the next morning. From the collet chuck, the hydro-expansion chuck and miller to the drill, thread cutting tool and indexable insert, we have the entire range covered. For machining processes in particular, we offer a large number of products from all common manufacturers for warehouse dispatch. Last but not least, customers can benefit from our successful in-house brands FUTURO and NERIOX, whose assortments will be expanded even further this year due to high demand!