SEPO AG – Programming and precision are fun

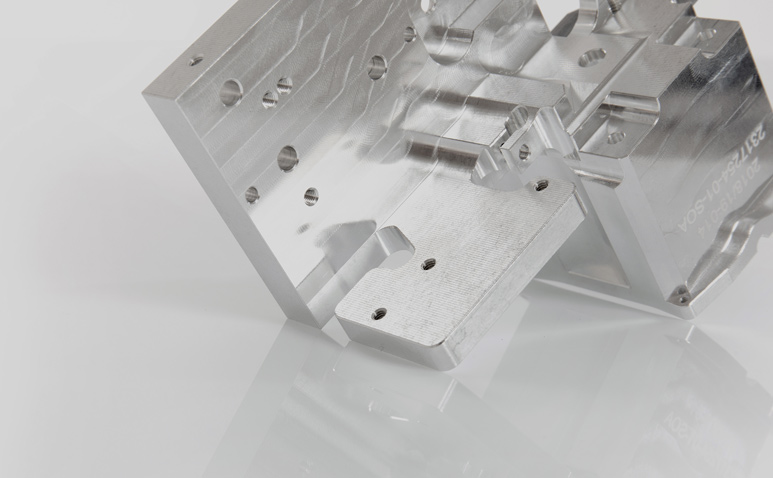

For many years, SEPO AG has been supplying medical technology manufacturers with precision mechanical parts for the highest requirements. The components often have complex geometry, tight tolerances and the finest surfaces.

This spring, the contract manufacturer from Bad Ragaz significantly expanded its production. This was due to the growing demand for components for pulmonary function devices used for the treatment of coronavirus patients. Within a short period of time this year, one of the existing orders, for which 1000 units were delivered last year, has therefore been increased to 1000 parts per week.

From one day to the next, managers Oliver and Danielle Oberdanner converted the warehouse into additional production space. Since March, the workforce has grown by six employees and the machine fleet by six CNC machining centres. In addition to medical technology, the family-owned company also supplies components for laser and textile machines, sports equipment, audio and acoustic equipment as well as for electronics production.

Precision mechanics

From career changer to second-generation family business

The Sepp Oberdanner company for mechanical precision parts was founded in 1988 as a contract manufacturer. The machine fleet was gradually expanded and increased to four employees. At the same time, the company was developing and producing its own fishing equipment: SEPO's Fario products. Due to the increasing number of orders from renowned machine builders, who are now part of the customer base, new halls were acquired in 2006 – and SEPO AG was created. In 2016, Sepp Oberdanner handed over the company to his son and his daughter-in-law, Oliver and Danielle Oberdanner, both of whom had previously worked in the company. The managing couple currently employs 20 people and has been training a production mechanics apprentice since August 2020. A new building is planned for 2021.

"This is our opportunity"

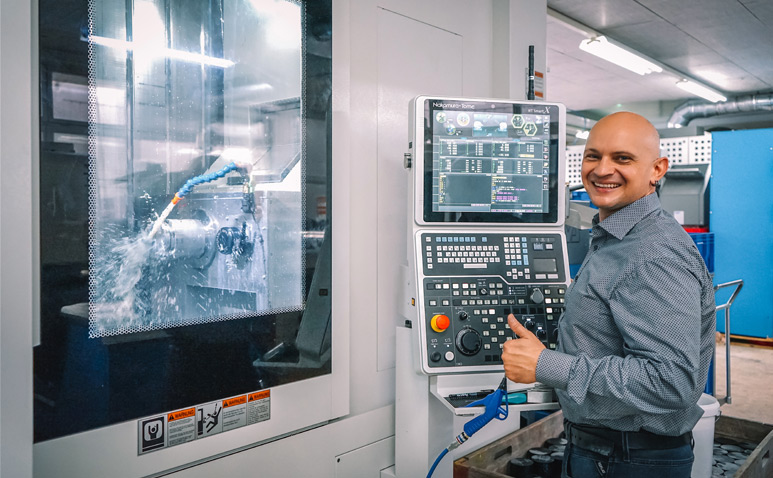

Since this spring, two systems, each equipped with a placement robot, have been in operation around the clock. Addressing automation, Oliver Oberdanner replies: "This is our opportunity and we must take it." He's referring to Swiss industry. The way in which he quickly unclamps a milled part here during the tour of the company and briefly modifies a CNC programme there to explain a process to us tells us that this man has complete mastery of all process steps on all plants. Yet a little later he adds: "However modern the machines are, the greatest potential is in the employees." Danielle Oberdanner adds: "We attach great importance to a respectful relationship with each other." During our visit, it is clear that the good team spirit here is built upon the flat hierarchies. "Just like in a band, the chemistry between members has to be right. It's not enough to simply master the instruments," sums up the long-time amateur country musician.

Bustle, good mood

The visibly motivated employees seem to welcome the fact that the company is bursting at the seams. Every movement is fast, every step is taken with a determination that many bosses only dream of. Despite the additional flexibility that has been required since the second quarter, the mood is very good. SEPO AG's core competence lies in CNC milling of aluminium components – Sepp Oberdanner, father of Oliver and founder of the company, already made a name for himself in this field. Automatic sawing, barrel finishing and deburring round off the programme; and steel, chrome steel, brass and plastic are also processed. After machining, most components are labelled by laser, cleaned ultrasonically and measured in 3D. The high quality expectations of the customers must be met reliably. And the company from eastern Switzerland sets no restrictions in terms of batch sizes either. They are able to produce prototypes, individual parts and small to medium-sized series within a short time. From the start, customer parts are optimised in terms of production technology.

Cooperation with Brütsch/Rüegger Tools

For years, SEPO AG has been purchasing tools and equipment from Brütsch/Rüegger Tools. The most recent example is the revolutionary cordless screwdriver Yokota YZ-T with no kickback. This high-quality assembly tool is extremely fast and guarantees constant workpiece clamping. This powerful screwdriver made it possible to combine pre-tightening and torque tightening into one operation during assembly. "With 80,000 screw processes in three months, this pays off," says Oliver Oberdanner. In addition to shorter setup times and cost savings, the tool increases comfort and flexibility, which in turn minimises the error rate. When the Yokota YZ-T was purchased, Brütsch/Rüegger Tools assisted the company from St. Gallen with optimising the assembly processes. Danielle Oberdanner is satisfied: "In general, we really value good cooperation. We have always appreciated the consistently open communication from Brütsch/Rüegger Tools. It is the basis of our mutual trust."