Trisa – a brush to get your teeth into

Who hasn't heard of the Trisa toothbrush? The extent of its production is evidence that it takes care of clean teeth far beyond national borders. At peak times, one million toothbrushes leave the Trisa plant in Triengen, Lucerne. The family-run company offers more than 100 different models: from the children's toothbrush and the whitening toothbrush to the toothbrush made of sustainable materials. The oral hygiene specialists are constantly developing new versions with even more ergonomic handles, tongue cleaner attachments or an improved ecological balance.

Along with interdental cleaning products such as dental floss and interdental brushes, Trisa also produces facial brushes, nail care sets and hair brushes. But it's the company's oscillating electric toothbrushes and sonic toothbrushes that are met with most enthusiasm on the technological stage. The Sonic Performance, for example, ensures flawless deep-cleaning with 40,000 sonic movements per minute – even in the spaces between the teeth.

Clean Swissness

Founded in 1887 as a manufacturer of hair and household brushes, the first toothbrush was produced in Triengen in 1903. As part of its first scientific collaboration with the universities of Zurich and Lausanne, Trisa developed the first toothbrush to have nylon bristles that were already mechanically rounded in 1952.

Today, Trisa AG exports more than 95 percent of its products to more than 80 countries and, along with four other sister companies, forms part of the Trisa Group. The company's successful development is based on a participatory management model and the resulting involvement of its employees. All 800 employees own shares in the company and are thus co-owners of Trisa AG, which is managed by the fourth generation of the Pfenniger family.

A drive for creativity

The vast proportion of products younger than three years old serves as proof of the significant role research and development plays at Trisa. Andreas Meier, Head of Workshop Technology at Trisa AG, explains: "We keep all of our processes in-house, which enables short time-to-market." So far, more than 800 international patent and design applications have been filed. The in-house innovation culture is one of the company's key factors for success, as is the expertise gained through many years of cooperation with leading universities and dental practitioners, which is continuously incorporated into product development.

Recycled PET material and wood on trend

Currently, both products and packaging are moving away from plastic towards cardboard. As Andreas Meier puts it more precisely: "Toothbrushes made of natural raw materials, biodegradable plastics or recycled PET materials are on the rise." As the people of Central Switzerland have demonstrated, a toothbrush can now be produced in a fairly eco-friendly way: A handle made of beech wood from sustainably managed Swiss forests (by the way, the first Trisa toothbrush also had a wooden handle), a brush head based on renewable raw materials, bristles made from a renewable raw material obtained from the castor plant, packaging made of recycled cardboard and PET film made of 100% recycled material.

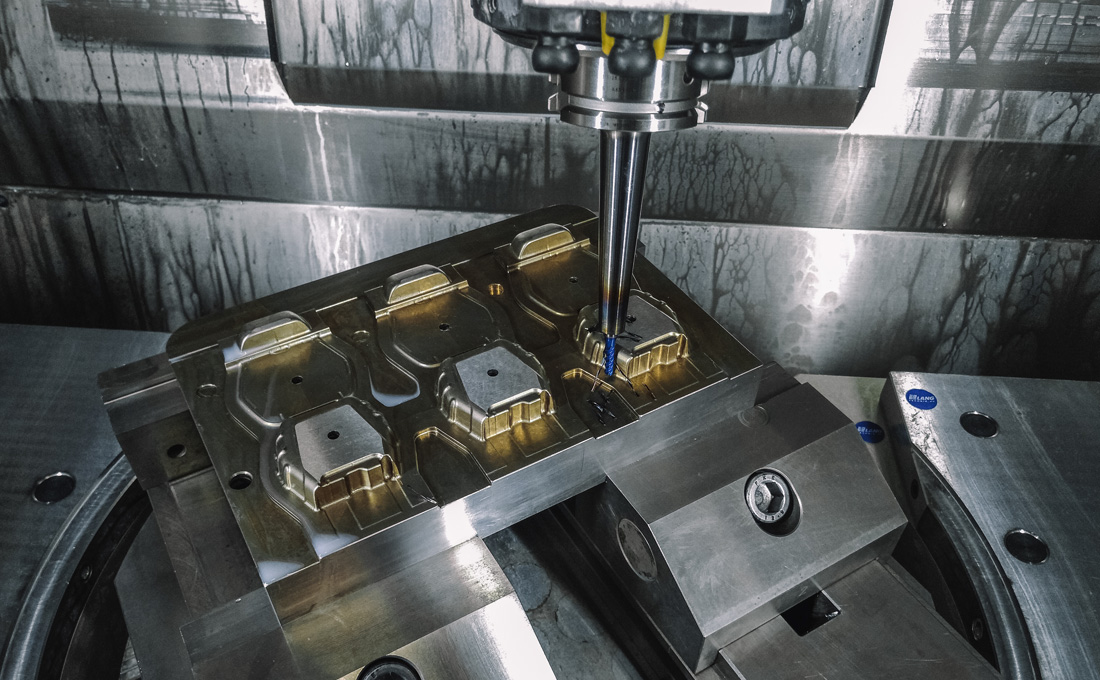

Collaboration with Brütsch/Rüegger Tools

A long-term customer, Trisa gradually intensified its cooperation with Brütsch/Rüegger Tools at the end of the 1990s. In the last five years, we have tested the use of new tools such as hard mills, ball cutters or end mills together on a regular basis. The increasingly close partnership is bearing fruit: The production of injection moulds, tools, equipment and packaging systems has been taken to the next level.

In addition to the mini-FUTURO range for tool and mould making, Trisa acquires a wide range of products via the ToolShop: handheld circular saws, protective equipment, cleaning devices, joining techniques, standard parts and general workshop needs for both assembly and production.