Micro-drilling as thin as baby hair

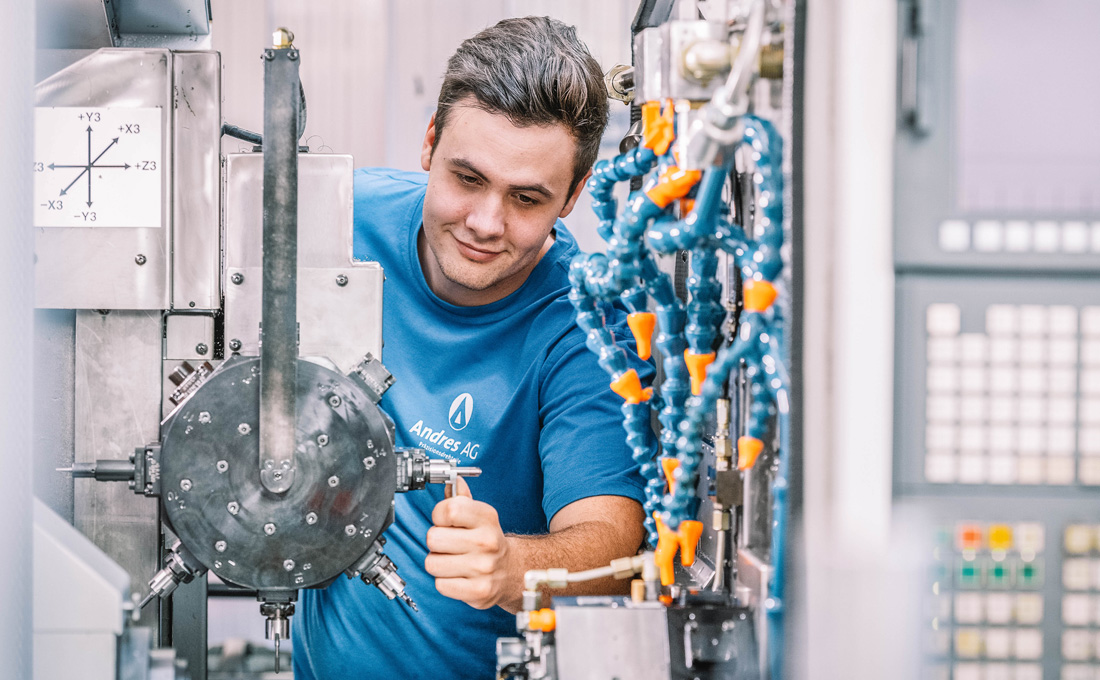

From the rod straight to the high-precision micro-turned part: workshop area with plain lathes.

"When others shy away, we say yes," explains Dominic Andres, Owner and Managing Director of Andres AG. This is based on the company's extensive expertise in implants and materials that are difficult to machine but are essential for the production of complex precision parts in the Medtech industry. One of his company's specialities is micro-drilling with a diameter of five micrometres, which is similar to that of baby hair.

Generally, challenging turned parts have a small diameter (0.1 to 20 millimetres) and a relatively large length. The fact that very close tolerances apply in this respect is only one of the many challenges. It is not surprising that many years of experience in the production of small-format components is a real benefit.

The plain turning specialists

Andres AG was founded in 1956 as a one-man company managed by Konstantin Bärtschi that produced screws and turned parts. Today, Dominic Andres, who has worked for the company since 1997, is the third generation to run the family business, which now has 22 employees. The company, based in Lohn-Ammannsegg near Solothurn, produces batch sizes from 10 to one million, around 30 percent of which are exported.

Various projects have been implemented in recent years to reduce environmental impact and improve processes. The most recent was a cooling water system, which was commissioned in 2020 to dissipate the process heat from the machines to create more consistent production conditions.

Specialists in Medtech components

Originally founded as a supplier to the watchmaking industry, Andres AG not only supplies medical technology with ready-to-install components, but also the electronics and aviation industries: From eye surgery instruments (ophthalmology) to connectors for high-tech sensors, this plain turning specialist produces small but perfectly formed components for various applications.

The Solothurn-based company has always been interested in new ideas: This was best demonstrated by an order from a new customer that opened the door to the Medtech sector in 2003. At that time, Andres AG produced the first cannulated bone screws, a screw type with a centre bore. Since then, the company has established extensive expertise in producing implants — it now generates more than half of its sales in the Medtech sector. Even during the COVID-19 pandemic—when many outpatient procedures were postponed and demand for medical services fell—the company continued to operate at full capacity.

Production on 50 plain lathes

To stay at the cutting edge of technology, Andres AG is constantly adding new equipment to its largely automated CNC machine fleet. The technical knowledge and manufacturing expertise of the workforce is just as important as the machinery, as this comes into play as soon as an order is placed. The engineers provide support to customers in matters of design, process validation and inspection planning.

The backbone of the workshop is made up of 30 CNC plain lathes and 20 cam-controlled lathes. Other methods such as deep hole drilling, high frequency milling, thread whirling, punching and whirling are also used. "We are a small business and as such, we are able to react flexibly and deliver on time," adds Dominic Andres. Once the components have been surface-treated and cleaned, they are supplied in bespoke packaging as requested by the customer.

Collaboration with Brütsch/Rüegger Tools

In addition to procuring its test equipment from ToolShop, Andres AG also receives support from Brütsch/Rüegger Tools in terms of digitalisation. The ToolBoxes for tool management that were commissioned last year are currently connected to the ERP system. Another ToolBox for test equipment has recently been installed.

"These intelligent systems bring us a whole host of improvements," said Dominic Andres. The tools make for shorter search times, increased availability and greater transparency in terms of consumption per order. The primary purpose of using the test equipment is to reduce the number of costly calibration processes — measuring devices are only calibrated when required.

The next step is to network all the machines to benefit as much as possible from the process data. The Shopfloor module of the Hive Digital Suite from Brütsch/Rüegger Tools provides the basis for this. It's the ideal tool for increasing efficiency even more.