Proven a hundred times over

In order to make intralogistics work well in manufacturing plants, Brütsch/Rüegger Tools developed the ToolBox system. Since then, well over 100 customers in Germany and abroad have started managing their tools, measuring and operating equipment with this intelligent dispensing system. What do these users have in common? They have become more efficient, have lower tool costs and benefit from significantly reduced process costs.

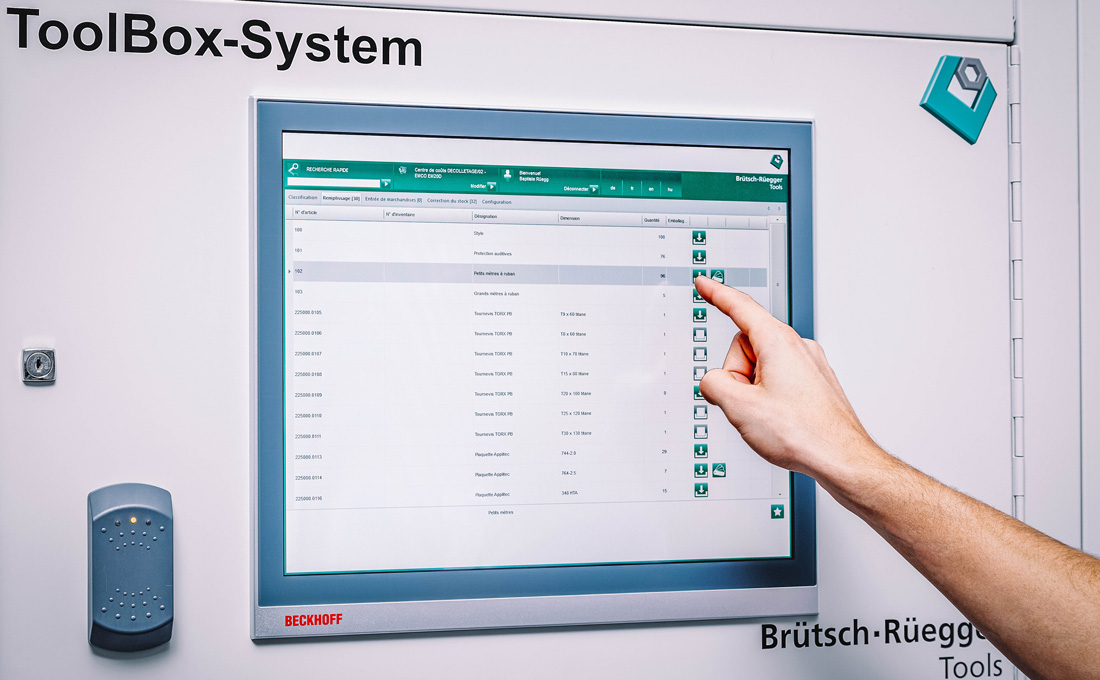

Originally designed as a storage and management system for tools, the ToolBox is now also used for small semi-finished products and machine parts, measuring devices or consumables. The spectrum of applications ranges from a single cabinet for one-person operation to a scaleable system that can expand as required with several dispensing stations per area/location for a large company.

But what makes the ToolBox so successful? In short: It increases productivity, helps to save consumption and procurement costs, is adaptable and quickly amortised!

InfoBox

Should your company consider a ToolBox solution too? Our experts will be happy to advise you without obligation! You can get a first impression here:

A secure investment

The ToolBox enables users to save costs on several levels simultaneously. The digitised management system accelerates search, withdrawal and return processes, minimising potential errors and reducing consumption. Manufacturing companies not only reduce their procurement and storage costs, they also gain in efficiency: A ToolBox systems achieves productivity increases of up to 20 percent per year. The flexible system can usually be amortised in less than a year.

The ToolBox also provides an important prerequisite: It creates order, transparency and traceability. This is very convenient for users of medical technology, for example, who have to comply with the new regulations. Inventory, the ToolBox software, makes all data available in an organised structure where it can be used for logging or documentation purposes. In addition, a system like this allows audits by customers or regulatory bodies to be passed with no problems.

Easy to integrate

Brütsch/Rüegger Tools began a success story with the installation of the first ToolBox system in 2010. Back then, the Industrial Solutions team had the idea of automating manual tool dispensing—cost-intensive in operation and maintenance—and making it ready for use around the clock. This has resulted in a great deal of success: Today, intelligent cabinet systems are even in use by customers in the USA and China.

What impresses users about the ToolBox system, is that both the cabinet and the software side can be adapted to individual requirements. The system can also be easily integrated into existing digital networks. It is based on an open technology that many companies already use to digitise their processes.

A stock overview and removal history are available at the touch of a button, while customers also benefit from automatic order triggering, pick list generation and evaluations. A big benefit is the needs analysis of the resources required to carry out a particular order. Further savings potential lies in the management of the inventory itself: As an aside, this can be completely outsourced to Brütsch/Rüegger Tools.

Also for measuring devices: The future is here!

Calibration processes from A to Z can be outsourced to a calibration laboratory via ToolBox using a digital interface: If a measuring device requires calibration, Inventory informs the user, calibration laboratory and Brütsch/Rüegger Tools. Our service immediately ensures that the measuring device is collected from the customer and brought to the laboratory, which is prepared for the calibration and possible repair processes. The measuring device is returned via delivery service and stored in the ToolBox. In the meantime, the calibration certificate is available in Inventory.

The customer is able to track the location of the measuring device throughout the entire procedure. The customer receives seamless documentation of all measuring devices including the certificates and all test data from the calibration laboratory.