SIAMS — Back with a bang

Finally, we were able to play to one of our proven strengths again — face-to-face customer advice. At SIAMS, Brütsch/Rüegger Tools demonstrated an incredible series of highlights for microtechnology, which were received with enormous enthusiasm.

This is SIAMS as you have never seen it before: After two years of video calls, Brütsch/Rüegger Tools celebrated its return to the public arena with a fireworks display of premieres. In addition to many new products and services for the watchmaking and medical technology industries, visitors young and old were also thrilled by new apps for the digital factory: "We were inundated with interested visitors with specific requests for new projects," says Loïc Châtelain, Strategic Account Manager for the Watchmaking Industry at Brütsch/Rüegger Tools. He and his colleagues felt in Moutier that the industry was buzzing again.

Connected by tradition

SIAMS is the highly specialised and high-profile showcase for the microtechnology and precision industry throughout the Jura mountains. The trade fair brings together the expertise of an extraordinary Swiss industrial region that does business with the whole world. Our role as partner to these innovative manufacturing companies has always been close to our heart. With our product range and our services for the entire value chain, we maintain a strong affinity with the production and operating materials of micro- and medical technology. This year's SIAMS took place from 5 to 8 April at the Forum de l'Arc in Moutier, Switzerland, and welcomed 440 exhibitors and 15,000 visitors.

We look forward to the next event, which is scheduled for 16–19 April, 2024.

A new product set for watchmaking and microtechnology

10,000 items for the watchmaking industry and microtechnology combined in a single product set and based on a solid supply concept — many dream of this, but could never imagine it. Brütsch/Rüegger Tools has made this dream a reality and débuted a sample of the new product set live for the first time. The focus was on optical 3D measuring instruments for the automatic testing of microtechnology components such as the flagships "Visio 200", "Scan 25" (Sylvac) and "QMT 100" (Qualimatest). Video microscopes and measuring equipment were also demonstrated.

The user-friendly and robust devices also epitomise the digital factory, which is networked all the way to quality assurance. Loïc Châtelain continues: "In Switzerland, we now not only sell the latest generation of 3D measuring devices, but also support companies with individual services and digitalisation." At the stand visitors were able to experience just what can be achieved with the new, intuitive measurement technology module of the Hive Digital Suite, Hive Quality Control, in conjunction with a digital caliper gauge.

Prospective customers were able to try out a range of state-of-the-art optical measuring devices at SIAMS.

Prospective customers were able to try out a range of state-of-the-art optical measuring devices at SIAMS.

Data transfer at the touch of a button with FUTURO connected: Measurement results are transferred to the active field on the computer, regardless of whether it is in an Excel file, Word file or other file format.

Data transfer at the touch of a button with FUTURO connected: Measurement results are transferred to the active field on the computer, regardless of whether it is in an Excel file, Word file or other file format.

Industry 4.0 tailor-made

The audience was also amazed by the dashboards of the newly developed module Hive Shopfloor. With the help of operational data recorded and documented in real time, area managers optimise all processes from machine utilisation to quality assurance. And most importantly: This not only creates transparency and optimises planning, but also provides a basis for making the right decisions. Raphaël Müller, Head of Industrial Solutions at Brütsch/Rüegger Tools, explains: "With the Hive Digital Suite, users increase productivity and expand capacities simply by using the power of existing data."

Hervé Geiger, Head of QA & Watch Atelier at La Montre Hermès, embraced the latest Industry 4.0 solutions with enthusiasm, in particular the Jellix IIoT platform. He said: "Brütsch/Rüegger Tools is not only the provider with the most options, but also the one who responds most quickly, both in the creation of quotations and in delivery."

High-performance tools for Décolletage

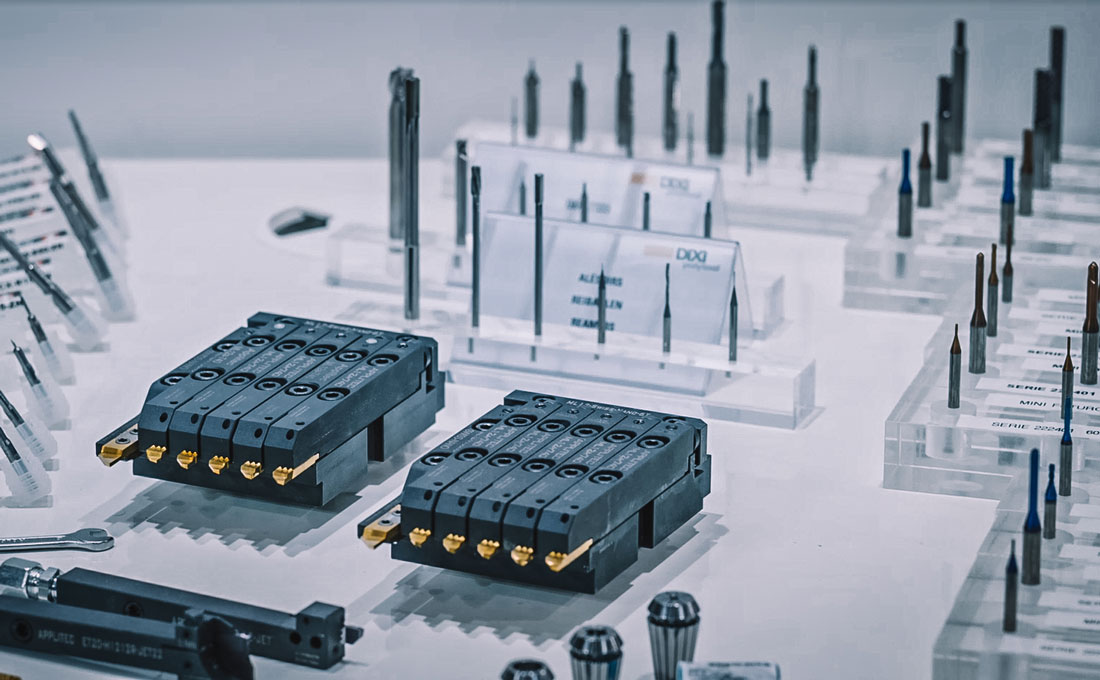

Whether in machining, measurement technology, assembly technology, personal protective equipment or standard parts, Brütsch/Rüegger Tools caused a stir with numerous product premières at SIAMS. The spectrum ranges from tool programmes for the watch industry and medical technology—including mini end mills from our own brand, FUTURO—to microsensor torque screw systems for the precise tightening of micro screws up to the toolbox system, which was presented live. Remo Feurer, Head of Administration at Weber Décolletage AG, was pleased with the friendly welcome and the excellent advice at the stand: "Our visit has put us back at the cutting edge of technology." It was the drills in the NERIOX series, in particular, that attracted Feurer's attention. "We appreciate the consistently high quality of Brütsch/Rüegger Tools. Our contact person Sergej Steiner always goes the extra mile and quickly provides us with solutions that stand the test of time."

Live test: Tool management system

At the Brütsch/Rüegger Tools stand, prospective customers were able to experience the entire production chain live. Using the touch screen, they entered the digital service portfolio of the digitalisation specialist. Laurent Charreton, Production Manager at AISA Automation Industrielle, was impressed by the tailor-made toolbox system and its compatibility with an ERP system. "At the Brütsch/Rüegger Tools stand, I received all the information I needed for implementation. We are currently evaluating the number of items that we will integrate into our new toolbox to calculate the investment." His visit directly triggered the modernisation of his company.

A great reception: Passion and positivity

After three years without trade fairs, the world of microtechnology was excited to come together again. As a multi-brand supplier and digitalisation partner, the teams from Brütsch/Rüegger Tools felt a great sense of optimism at SIAMS. Moutier witnessed lively networking in a friendly atmosphere and a connection to new communities. When the WiFi went down across the entire trade fair due to high traffic, it was even met with positivity.