We will be at the Swiss Plastics Expo 2026 –

Tools. Next Level.

From 20–22 January 2026, you can find us in Hall 2, Booth B2042.

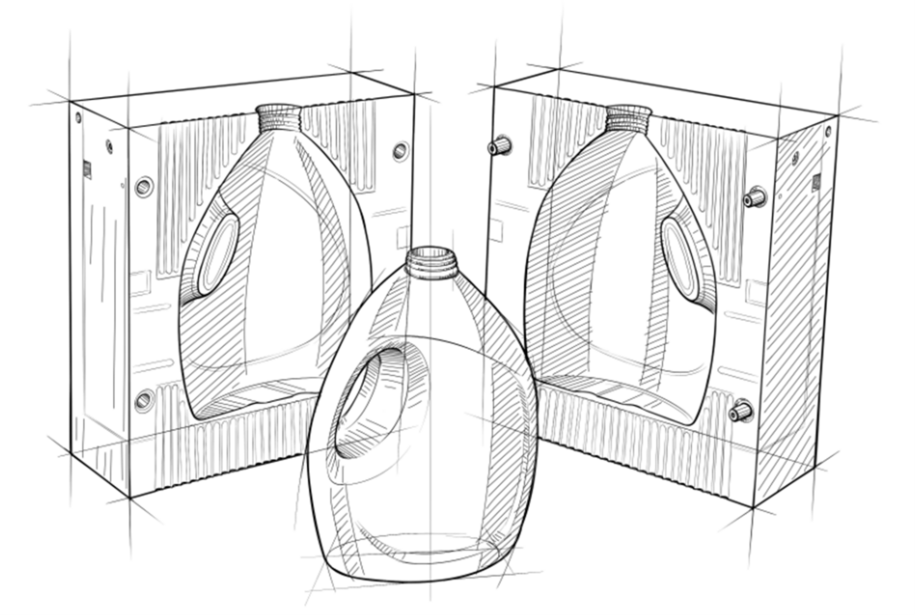

Brütsch/Rüegger Tools is your partner for smart, well-engineered solutions—whether standardised or tailored to your specific needs. Our offering includes a broad and comprehensive portfolio in toolmaking, stamping technology, and plastic injection moulding.

The Swiss Plastics Expo brings together the entire plastics industry and showcases innovative, efficient, and future-oriented solutions. Use the trade fair to gain fresh inspiration – and discover products with us that will significantly advance your manufacturing processes.

We look forward to welcoming you!

Our key topics:

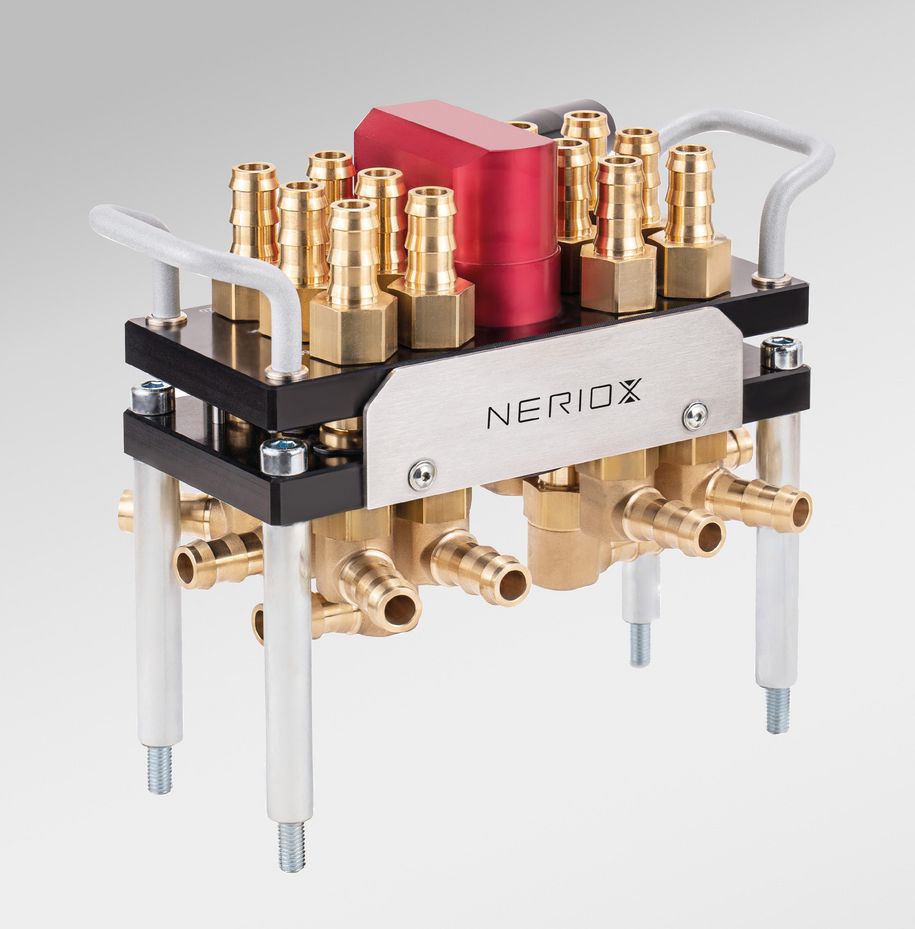

NERIOX Temperature Control Technology – uncompromising safety for a wide range of applications

Toolmakers and plastics processing companies rely on couplings and fittings that are exceptionally robust, durable, and temperature-resistant. The reason: they are used for heating and cooling mould assemblies in injection-moulding or die-casting applications and must withstand extreme temperatures.

For these demanding temperature-control applications, Brütsch/Rüegger Tools offers a comprehensive product range consisting of quick couplings (European and international plug profiles) as well as hose solutions, including all necessary connection components.

BORDIGNON Gas Springs – durability and reliability

The gas springs of the BORDIGNON AUTOMOTIVE LINE stand out for their high reliability, immediate readiness for use, and excellent price–performance ratio. With integrated safety systems compliant with ISO and VDI standards, they provide maximum safety even under extreme conditions.

AHP Merkle Hydraulic Cylinders – for the highest demands and complexity

Hydraulic cylinders are often used to demould undercuts in complex part geometries. They typically operate in a pulling motion. At the beginning of the stroke, very high forces are required because the solidified plastic still adheres to the core.

A high-quality product range and various configuration options are available to our customers.

Live metrology at the booth

At our booth, we will present modern precision metrology, including the FUTURO height-measuring device, which delivers precise and reliable measurement results via a clear two-line LCD display. With its integrated air cushion, it can be moved effortlessly, offers a measuring range of up to 400 mm, and enables easy data transfer via RS-232, USB or Bluetooth – ideal for accurate height, depth and diameter measurements in the workshop.

Additionally, you will find a high-quality surface-roughness tester, as well as outside micrometers, digital calipers and dial indicators from leading manufacturers.

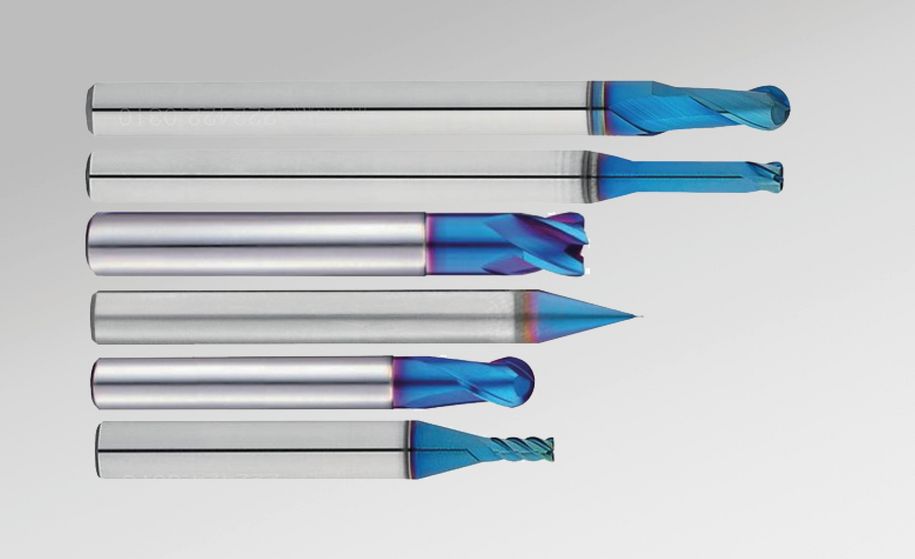

Reducing machining times and process costs, increasing tool life and process reliability, and making optimal use of existing production capacities – this is the clear goal of our application specialists.

Brochure sneak preview

The full brochure will be available at the trade fair – but we are already offering you a compact preview of the latest solutions in tool and mould making: from innovative components and modern materials to advanced machining technologies.