For the best tools and moulds

They are not in the spotlight like high-tech machinery but are just as essential for production: Standard parts and technical components. For more than two decades Brütsch/Rüegger Tools has been supplying the largest stock of standard parts in Switzerland to the tool and mould making and punching technology industry. The non-manufacturer-specific range of 70,000 items allows companies to choose the most suitable solution from a wide range of products: They cover 90 to 95 percent of daily demand. Thanks to having established optimum relations with suppliers and having the highest levels of available stock, manufacturers not only benefit from reduced procurement costs, but also from the shortest procurement times.

Brütsch/Rüegger Tools shows that even a range of products put together put together over years can continue to be perfected by responding to three trends. Increasing diversity and rapidly changing standards and regulations, increasingly complex parts production and the increased demands placed on end products. As a full-spectrum provider, we are taking these trends into account and are also increasingly helping customers to procure customised standard parts.

Roberto Fasanella is now in charge of the Standard Parts division

Since September 2020, Mr Roberto Fasanella has been in charge of the Standard Parts division at Brütsch/Rüegger Tools. With more than 20 years' experience in the industry, the soon-to-be father of three, active football player and coach has the necessary knowledge of standard parts and technical components. Roberto Fasanella: "I see my role as being to significantly develop my product group over the next few years and to provide our customers with the best possible service every day".

For more than 20 years, Brütsch/Rüegger Tools has been supplying standard parts and technical components to the tool and mould making and punching technology industry. A team made up of six professionals with training in mechanics and long-term practical experience supports customers in all matters.

Contact our Standard Parts specialists directly on +41 44 763 63 63 or verkauf.normteile@brw.ch!

Comprehensive services

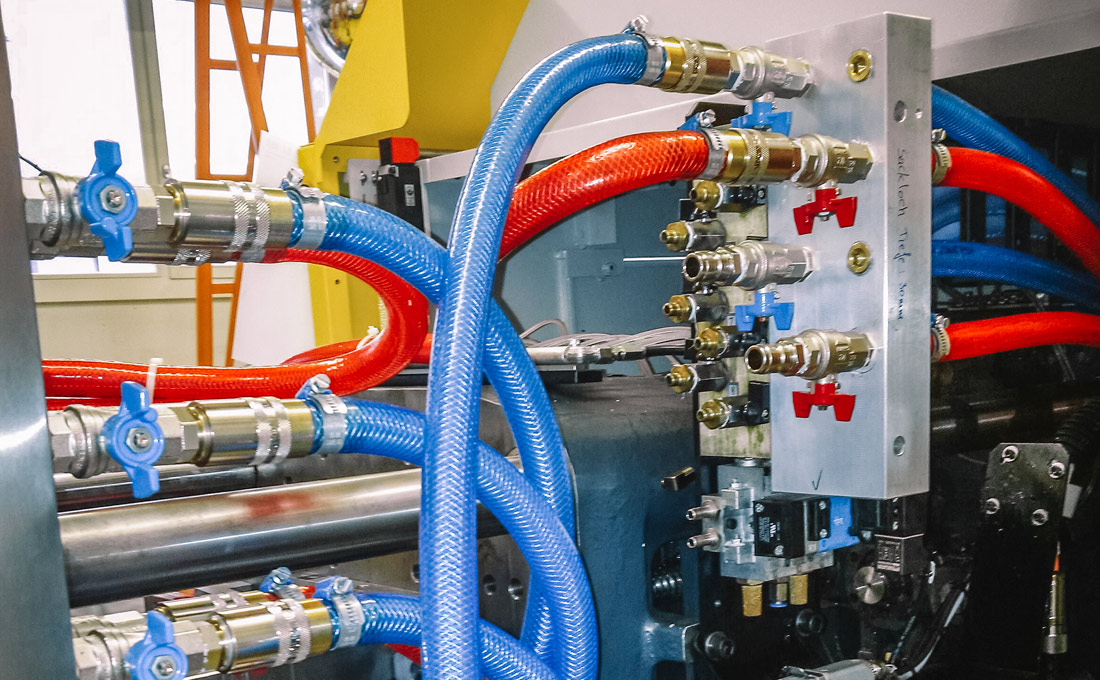

With a special range for mould making, specifically for injection moulding, punching and forming technology and general mechanical engineering, the ToolShop offers everything you need to run a workshop to a professional standard: From ejectors, sleeves, cutting and centring elements to guides, mould markings and couplings, to items related to compressed air technology, pneumatic technology and fluid technology. This includes accessories, such as hoses for plastic granulates, a comprehensive joining technique range and parts for machine construction such as bearings, bushings, springs or sealing elements.

Roberto Fasanella, Head of the Standard Parts division at Brütsch/Rüegger Tools, explains: "We make sure that the correct technical component with the ideal design is ready for use when its needed in the injection mould or in the punching tool". Thanks to the large schedule-orientated stock for make-and-hold orders, the service to process third party items, standard parts as well as parts made out of customer drawings, Brütsch/Rüegger Tools guarantees customers a comprehensive and tailor-made service.

Developing individual solutions

In addition to offering standard items to meet all established factory standards, the standard parts experts also help coordinate special components. "Working together with the customer, we develop ideal solutions and minimise the risk of errors in customised components in the fields of injection moulding, punching and deep drawing", continues Roberto Fasanella. The specialists from Urdorf draw on a wealth of experience to help the customerdesign special products with the most exacting specifications.

"As we work closely with more than 100 partners and manufacturing plants worldwide, we are able to offer a wide variety of options and thus ensure that all customer needs are met", adds Roberto Fasanella, announcing: "We have a number of interesting projects in the pipeline". We'll stay tuned!

Knowledge transfer as an additional service

The huge advantage for customers in the tool and mould making industries, as well as the punching technology industry, continues to be the ability to access the entire range in the ToolShop. Orders for operating materials, tools and any other industrial requirements can be made at the same time and at no additional cost from the same supplier.

In addition, we at Brütsch/Rüegger Tools are convinced that long-lasting customer relationships are based on shared, constantly expanding knowledge. Are you already familiar with our field-tested publications? Call us on +41 44 763 63 63 and we will organise free delivery for you straight away!

- NormBook, Edition 4

- Joining Technique booklet, 2019 edition

- ToolBook, Edition 2019